Practically all general contractors have heard about building information modeling (BIM), but what are the applications of this breakthrough technology in real life? In 2015, we checked in with Russell Gibbs and Shawn Mancill at Brasfield & Gorrie, one of the nation’s largest privately held construction firms, to learn more about how they are tying together BIM in the office and the field.

Brasfield & Gorrie, a leading general contractor based in Birmingham, Ala., manages high profile projects throughout the southeast. The firm has used Autodesk Point Layout (APL) on a number of healthcare, commercial and federal projects to gain efficiency on their self-perform concrete layout projects.

With APL and Leica Geosystems robotic total stations, they make sure that what has been modeled is accurately replicated and built in the field.

“One of the biggest issues in construction is the duplication of work – especially when it comes to drawing and getting information out of documents,” explained Mancill, Brasfield & Gorrie’s virtual design and construction coordinator, in a recent Autodesk University presentation. “For years, we’ve used traditional 2D for layout. Now we’re able to actually see what we’re constructing before we construct it.”

The firm began using APL, a plug-in to Autodesk Revit, to ensure that all of the layout responsibility stayed with the field engineers and to integrate them with the overall VDC (virtual design and construction) process. They also wanted a tool that would support their current equipment and processes.

Project No. 1: $10 Million Administration Building

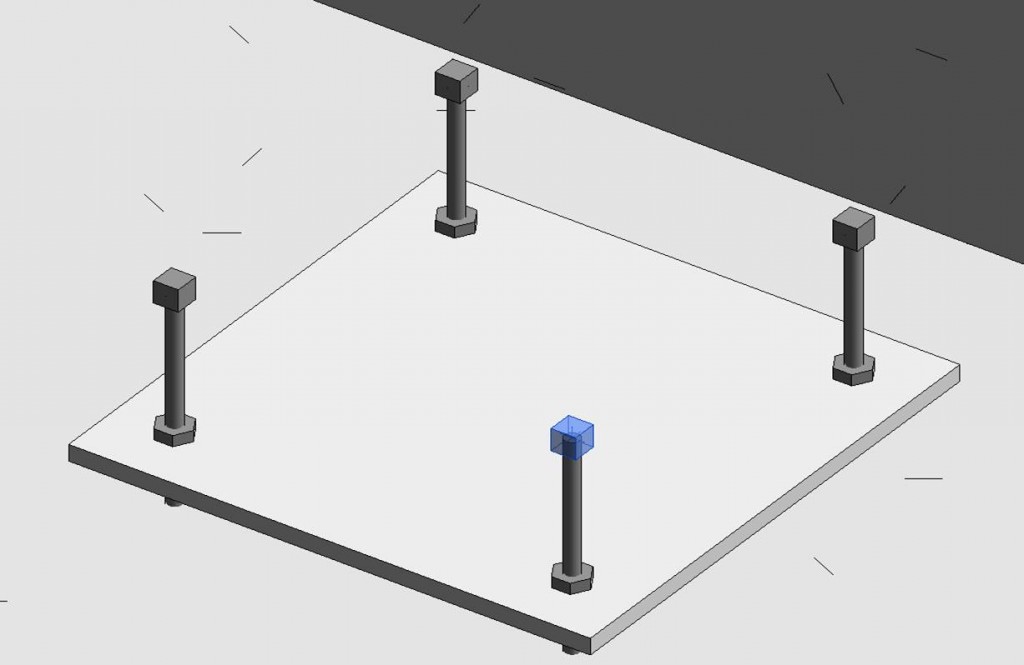

The firm’s first real use of APL integrated with Leica robotic total station hardware was for backchecking anchor bolts and the foundation layout of a 40,000 square foot, $10 million administration building.

Brasfield & Gorrie’s VDC group, in conjunction with the field layout team, tested the accuracy of model data for layout as part of the project. This was a critical step for the field teams to trust models for construction. The VDC team built a model, then worked with the field engineer to shoot the points in the field to validate the model, checking it for accuracy. The field engineer then applied his own points in the model, in place of doing a manual calculation, and exported those points to perform the layout.

“Not only were we able to check the accuracy of the model, but we were able to check the accuracy of the layout in comparison to the model,” said Mancill. “We validated what the model produced and found that we were actually generating information that was just as accurate as what the field engineer was creating with his manual calculation process.”

The level of accuracy of the process wasn’t all they learned in this pilot project. It was also a lesson in how information is created and pushed to the field and served as the first step in getting everyone on the same page with the technology.

“It really wasn’t about testing the software or Leica’s hardware – it was about trust and ownership of the information between the VDC guys and the guys out in the field who take ownership of where that point is marked on the ground,” said Russell Gibbs, regional director of virtual design and construction for Brasfield & Gorrie. “Once we broke down that barrier of trust and established a workflow, we were able to get momentum that we carried on to other jobs, and then the word spread.”

Project No. 2: The Concrete Box

On another project, Brasfield & Gorrie was tasked with installing concrete in a building best described as a “concrete box in the middle of the city.”

This was a complex project, not only because the building is very, very heavy concrete, but also because the firm had models of conduit that had to be coordinated and installed. Using APL and a 3D model, the team was able to compare the as-built drawings to what was installed to find discrepancies and to backcheck the points to verify as they were installing the concrete.

“We would have the field engineer send us his as-built points in a CSV file and then put them in the model to verify that what they were installing in the field matched our model,” said Gibbs. “The coordination was really the key component here and making sure that as we brought prefabricated systems to the site that they would actually fit properly.”

Because of the heavy equipment involved, the firm had to check for flatness in the slab to see where there were depressions. The project served as a “test” for teams to begin using the Leica Nova MS50 MultiStation – a high-definition scanning total station – with APL for slab flatness analysis.

For example, there was a wall where a concrete panel on the side of the building looked like it was bowing a little too much. Crews had a Leica Nova MS50 MultiStation onsite and used it to check the flatness of the panel to see if it needed to be adjusted or replaced.

“We actually shot the points on the panel and pulled them into Revit via APL and saw that this panel met tolerance and didn’t have to come off the building,” Gibbs said. “By doing that, we were able to avoid something that could have been a big problem for us.”

Project No. 3: Grandview Medical Hospital

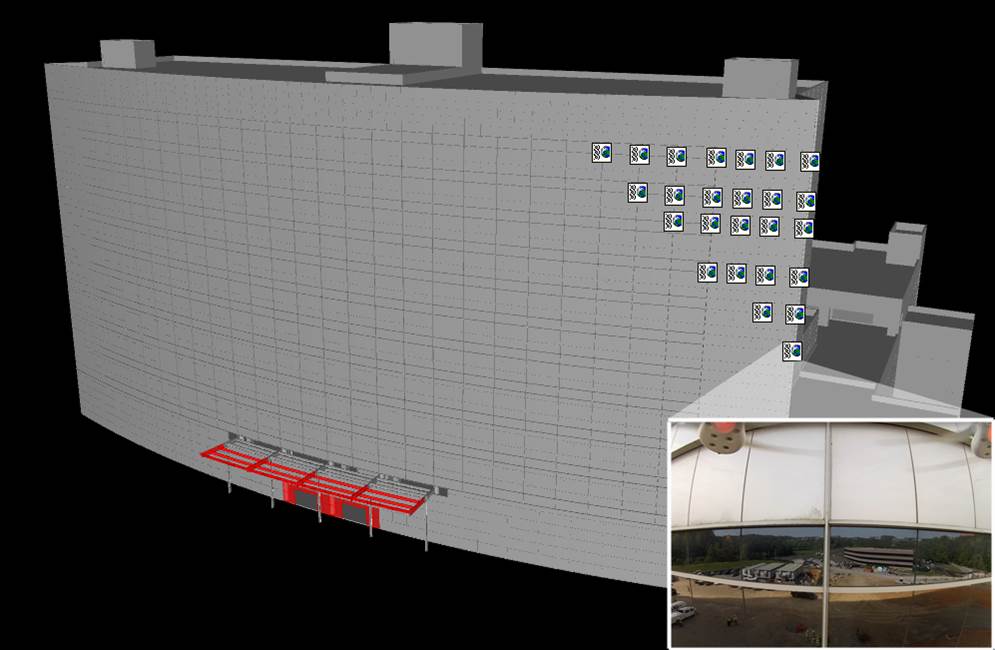

Grandview Medical Hospital in Birmingham, Ala., was a challenging project. Construction was halted years prior until new owners came in to complete the construction. Brasfield & Gorrie’s teams were challenged with verifying the existing conditions of the exterior curtain wall. A quality inspection was required to assess the current state so the repairs could be quantified.

The traditional solution is to drop a swing stage off the building for manually inspections. But armed with a model from the design team, Brasfield & Gorrie partnered with Auburn University to come up with a better plan that leveraged technology.

“We were able to explore the use of drone technology to attach points with APL in Revit and then attach images to those points,” said Gibbs. “Then we could put the URL of the image in that APL point so that when it went to Navisworks as our deliverable to the representative or inspector, we would basically just have to deliver one model.”

The team developed a concept that would allow them to deliver a model with points at every intersection of the inspection area. The drone could take an image that the inspector could then click on to see the picture and even add his comments.

“This approach could really help us organize the deliverable plus manage and track thousands of images. We would know that it actually came from one spot, how it was inspected, and how it was approved,” Gibbs said.

To learn more about how Brasfield & Gorrie uses BIM in the field, watch this encore of the 2015 Autodesk University presentation, a popular session that was sold out two weeks before the conference. For more information about how you can apply BIM solutions in your business, please contact us.