Brad Condray

Comfort Systems

Concrete/MEP demographic

Set/up/Situation:

Comfort Systems USA has become America’s leader in installation and service for building mechanical systems. Over the years, the company has merged with the best regional experts, and provide nationwide reach through 37 subsidiary companies that are prepared to build, service or retrofit any mechanical, HVAC or electrical system.

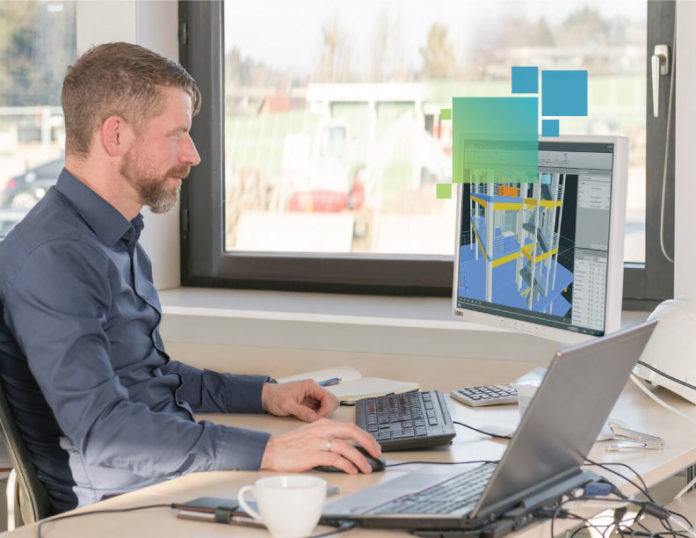

Comfort Systems USA uses Leica Geosystems equipment and software due to ease of use, reliability and time saved in the field for its mechanical, electrical and plumbing (MEP) projects.

“Leica Geosystems stands on their reputation. Leica is all about their products and their reliability to do what they say they can do,” said Brad Condray, Vice President of Operations, Comfort Systems USA. “We needed the reliability to tackle the University of Alabama job in Tuscaloosa. It’s the biggest dorm build in the state of Alabama and it’s on track for a 2022 completion.”

As the state’s flagship university, The University of Alabama encompasses 1,200 acres and is home to more than 38,000 students. Continued growth had the university in need of additional student housing and in XX, the school selected Comfort Systems USA to build a new state-of-the-art dormitory to house approximately XX students and XX.

Challenge/Results:

[Insert background on the job, challenges, etc. with this type of build]

[Transition into the Leica/Comfort Systems story.] Comfort Systems is doing all the piping, plumbing sheet metal, etc. layouts using Leica Geosystems’ iCON series [insert others as needed]. We’re routinely catching issues for the general contractor with Leica Geosystems’ iCON series.

As Comfort Systems aligned with its BIM department to shoot inserts down into deck, it became the first project where they’ve been able to fully leverage capability of Leica Geosystem’s iCON series. The BIM department relied on Leica for assistance with BIM drawings and to transfer data. Leica was able to save Comfort Systems USA money, manpower and reduce time in the field. Previously, it was a manual process that took two and a half days – with two-to-three staff members – for all MEP sleeves on a deck. With Leica Geosystems, Comfort Systems is now able to do that in less than a day with just one staff member. Recently Comfort Systems starting using robotics, saving resources on human capital and ensuring precision and efficiency.

An industry known to be slow to embrace technology, there’s now a resurgence of talent who understand and know how to make digital planning the priority. While some of the younger professionals may lack experience, which can lead to issues, technology from Leica Geosystems can help address the gap in experience. With Leica Geosystems, Comfort Systems is moving away from the traditional analogue layout methods of managing and planning, and moving toward fully digital layout techniques and workflows.

[Close with a bit more on Leica, the current phase of project, what’s ahead and any projected benefits to follow]