As the construction industry continues to evolve, the adoption of building information modeling (BIM) has emerged as a crucial factor in achieving efficiency and cost-effectiveness. By embracing BIM and staying ahead of the technology curve, contractors can boost efficiency, accuracy, and savings through self-validation of work and accurate progress billing.

Understanding BIM

BIM is a digital representation of the physical and functional characteristics of a construction project. This includes the creation of a “digital twin” — a virtual representation of a site’s real-world counterpart. And while BIM has existed since the first CAD design models, it has evolved into collaborative platforms that integrate 3D design models and reality capture.

For heavy construction, BIM enables contractors to visualize a project before starting work, perform the construction to match the design, and then utilize tools like laser scanning to ensure that there are no material discrepancies between the design and actual construction.

Cost Savings Through Self-Validation of Work

Traditionally, construction projects often incurred substantial costs due to rework resulting from design deviations or errors. But with BIM, contractors can validate their work in real-time, ensuring that the construction aligns precisely with the project’s design criteria.

Troy Dahlin, vice president of Heavy Construction for the U.S. and Canada at Leica Geosystems, part of Hexagon, says laser scanning is key to project validation.

“For example, with stormwater retention/detention ponds, volume becomes very important,” Dahlin explains in a ForConstructionPros GroundBreakers podcast interview. “We excavate the detention pond and place structures to control the flow of water. With laser scanning, we’re then able to scan the pond and get extremely accurate data about whether the pond’s volume meets or exceeds the design criteria.”

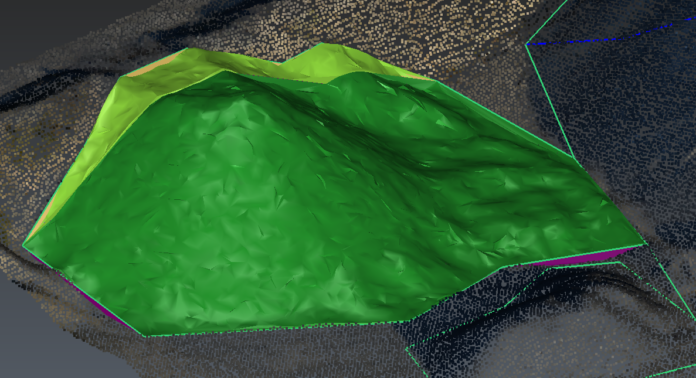

Or imagine if a contractor constructs a slope on a large earthmoving site. With conventional methods, a surveyor may take a few points to estimate the slope’s grade. But in a BIM workflow, laser scanning is used to create an immersive point cloud, offering billions of points to validate the work. This prevents costly rework and streamlines the use of materials, labor, and equipment hours.

“With a point cloud, we can say with absolutely certainty that what we’ve done is correct,” Dahlin says. “If I’m able to quickly validate that the slope meets the design criteria, I can confidently move on to my next task and not worry about coming back.”

Accurate Progress Billing: From Estimation to Precision

Inaccurate progress billing has long been a concern for contractors in the construction industry. Traditional methods relied on manual measurements, which could lead to estimations and disputes during billing processes. With BIM, contractors can confidently submit precise amounts of completed work based on real-time data collected during the construction process.

Dahlin explains, “If I were to go onto a large earthmoving site and take a topo grid, I have to connect lines, believe I don’t have grade swings, and come out with an average of the surface. BIM allows me to submit for precise amounts of earthwork since I literally have points every few millimeters in the point cloud.”

Embracing the Future of Construction with BIM

As technology continues to evolve, BIM is becoming more accessible, user-friendly, and seamlessly integrated into construction processes. The blending of technologies such as machine control, laser scanners, and digital workflows into a single solution allows contractors to build with more complexity but in a much simpler interface.

Looking to the future of BIM as the technology further develops, Dahlin says, “It’s going to be an exciting next several years.”

To speak with a heavy construction expert who can guide you on your data management and technology journey, contact us.