Truebeck Construction is a leading general contractor in the San Francisco Bay area and Portland. With nearly 500 employees, Truebeck has the expertise and resources to build highly technical projects such as laboratories, high-tech campuses, data centers, higher education facilities, and biotech and life sciences operations. A testament to their work: 80-90% of business is from repeat clients.

As part of the fall out of the pandemic and remote work, Truebeck has seen an uptick in customers wanting to convert office space into labs. Office buildings are typically shorter with 13–14-foot ceilings, whereas floor-to-ceiling heights in labs generally are 16-18 feet to accommodate the required utilities. In converting office buildings into labs, Truebeck scans the building and floors to ensure the new design will work within the existing building footprint. To ensure a reliable conversion, Truebeck uses Leica Geosystems’ RTC360 to capture existing conditions and utilizes the point cloud as background for the design team to validate or troubleshoot discrepancies.

While Truebeck has always used scanners, they have been a Leica customer for less than a year. In that short time, they have experienced remarkable gains in the field, utilizing scan data to provide insights into field conditions, improve workflows, share project information, and mitigate risk.

With their previous scanner, Truebeck spent an entire day out in the field to scan. Once back in the office, it took another day and a half to register the scans together. We had to assume the scans captured what was needed. We did not have an easy way to field-check the data.

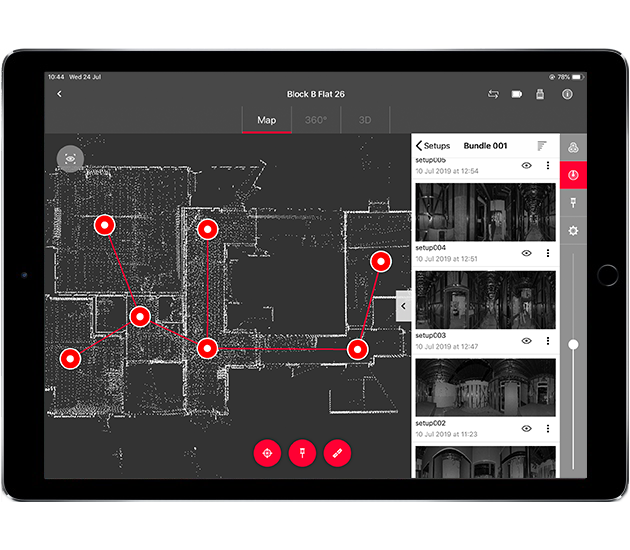

Since switching to Leica in September 2020, Truebeck has seen a drastic improvement in scan speed and quality and spent much less time scanning and registering. “The mobile Field app allows us to see what we have captured. When we scan using the Leica RTC360, we’re confident we’ll get quality data,” said Michael Vachon, Construction Technology and Innovation Manager at Truebeck Construction. “We know that when we leave a job site, we have what we need. That’s huge.”

Add to that Truebeck’s reduced human capital and simplified data collection, the company is realizing approximately two-to-three times improvement on registration. Black and white scans are, on average, 50% faster, and color scans that used to take 5-6 minutes are now captured in seconds.

“Because of the time saved in scanning, we’re now doing significantly more color scans which are incredibly helpful since color scans help identify the utilities,” said Justin Porter, Construction Technology and Innovation Director, Truebeck Construction. These new workflows allow us to perform QA/QC checks during our projects to ensure everything is in the right place. “We use Leica for quality control to ensure as-built integrity,” added Vachon.

The Leica RTC360 3D reality capture solution empowers Truebeck to document and capture their environments in 3D, improving efficiency and productivity in the field and the office through fast, simple-to-use, accurate, and portable hardware, and software.

The RTC360 3D laser scanner is the proven solution for professionals to manage project complexities with accurate and reliable 3D representations and discover the possibilities of any site.

“It’s been a true partnership between Truebeck Construction and U.S. CAD,” says Linda Gerety, Leica Business Executive at U.S. CAD. “Michael Vachon, Justin Porter, and the rest of the project team are examples of leading-edge thinking. Truebeck capitalized on the opportunity to switch from a less innovative scanner to Leica’s robust RTC360 resulting in better project outcomes through time savings, quality, and workflow efficiency. By partnering with U.S. CAD, experts at reality capture technology and consulting, Truebeck is equipped with the right solutions to drive construction innovation and efficiencies for their clients now and into the future.”