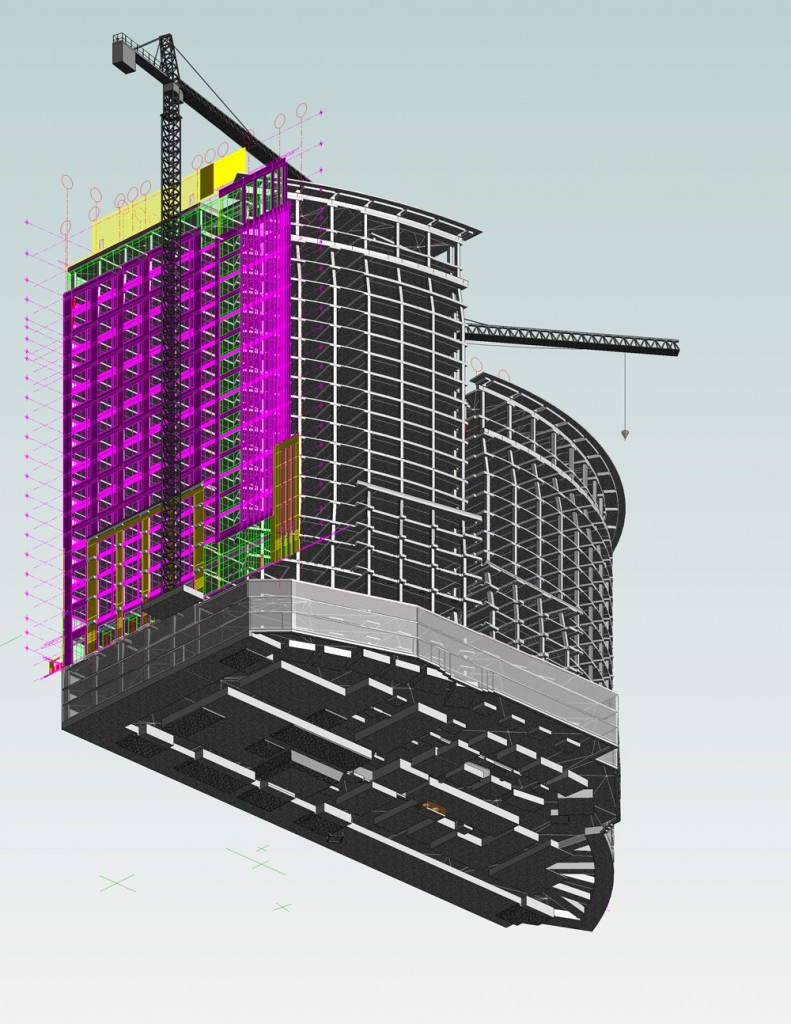

“Previously we had been using 3D models for early detection of missing or conflicting information and other potential problems in the 2D drawings by modeling the geometry of buildings,” said Scott Hover, Facchina’s BIM manager. “Now we are using BIM, not only for RFI and design clashes, but also for creating 4D schedules, quantity checks when ordering concrete, providing column schedules with accurate heights for field use and integrating field survey.”

Facchina is using BIM for layout and to participate in virtual design coordination efforts. So far, both the field teams and the back office are impressed with the results.

“At the most basic level, our crews in the field now have a visual picture of what they are framing up, wherever they are working, rather than just taking direction from layout engineers or a foreman,” said Hover. “Now they can actually see it, which makes a huge difference.”

A Different View from the Field

Facchina is using Leica iCON robotic total stations and Leica iCON tablets – both of which they purchased for this specific job.

“With the Leica system, I have three permanent targets on the jobsite,” said Melvin Nolasco, Facchina’s field engineer in charge of layout for the concrete frames division. “I can set up the total station with just one click using the set-up pilot feature, which is a huge timesaver.”

Point layout software is used to create the points in the model, which are then e-mailed to the layout engineer. He then copies the files to a USB stick and loads them onto his Leica tablet in the field to create the layout.

“We don’t even have to stop working or take the tablet to the office,” said Nolasco. “We just put the files into the data collector and keep working.”

On its next project, the firm plans to enable the jobsite with wifi so that files can be sent directly to the tablet.

Not only has BIM made the construction process more efficient, but it has also been very cost effective. Scheduling and material estimates are more accurate, and reworks have been drastically reduced because potential clashes can be detected before construction.

“Rework has been reduced,” Hover said. “Another big benefit has been the ability for everyone – from the field all the way to the supervisor level – to plan months ahead. That has been invaluable.”

On this project, the design team is producing a 3D construction model, broken apart by approved pour sequencing, for the concrete layout including slab opening, column location and slab edge.

“The very early return on investment on the equipment is being able to find conflicts within the drawings,” said Hover. “I have the opportunity to build in a virtual environment before we mobilized anyone to the jobsite. If I find potential clashes that can impact cost and the schedule months in advance before our guys even get out there, it pays for itself. That in itself is worth the investment in the hardware and software.”

What’s Next?

Facchina has been so impressed with the results that they plan to purchase another robotic total station this year and extend their use of BIM beyond layout to include 4D scheduling.

“With 4D scheduling, we can check the logic of the project manager’s schedule because you can see the planned activities in real time,” said Hover. “We’ve even heard of people doing 5D schedules where they can cost load the model.”

Hover said that as it becomes more commonplace to use BIM in the industry, more and more general contractors are requiring subcontractors to participate in their virtual design efforts. This has required field crews to learn some new skill sets.

“At the very beginning, there was some resistance, which is natural when there is a change in the workflow. But now that our teams have seen what BIM can do and have been trained on how to use it, just about everyone from the CEO to the foremen see the value,” Hover said. “A lot of our layout engineers are even interested in doing some of their own 3D work for their own layouts.”