For many construction contractors, building information modeling (BIM) is primarily an office tool that provides valuable insights before crews begin their work on the jobsite. From there, however, the model is often converted to a 2D drawing that is familiar but limited in the amount of data it can offer. Construction crews proceed the best they can with the information at hand, using plumb bobs and tape measures to complete the layout process. The real-time field data that is essential to a successful BIM process is lost through critical gaps that are generally accepted as the norm.

Bridging these gaps requires three key steps that connect the field with the office for a complete, highly intelligent BIM cycle.

- Inform the model with real-world conditions. Many models are developed from as-built paper drawings that are outdated and inaccurate, which leads to problems in the field during construction. Beginning with a solid foundation of accurate, reliable information is imperative to avoiding rework and streamlining the process. One easy way to take the guesswork out of the equation is by using laser scanners to capture real-world conditions. The resulting as-built point cloud can then be converted to an as-built model or used natively to inform new construction. This practice can be applied to renovation projects, demolitions and any situation where documenting the existing space can provide valuable intelligence that reduces rework and waste.

- Enrich construction layout with accurate model data. We live in a 3D world and design three dimensionally, so crushing a construction model down to a 2D drawing is counter-intuitive. The longer we keep the information in 3D, the longer we’re able to maintain the integrity of the highly coordinated 3D model. By using highly accurate multistations or total stations or combined with intelligent software, we can apply construction layout points to the model and then automatically transfer those to the jobsite to can create a “paint by number” plan for the contractors and installers. Enriching construction with high levels of accuracy streamlines processes, reduces the risk of errors and improves predictability.

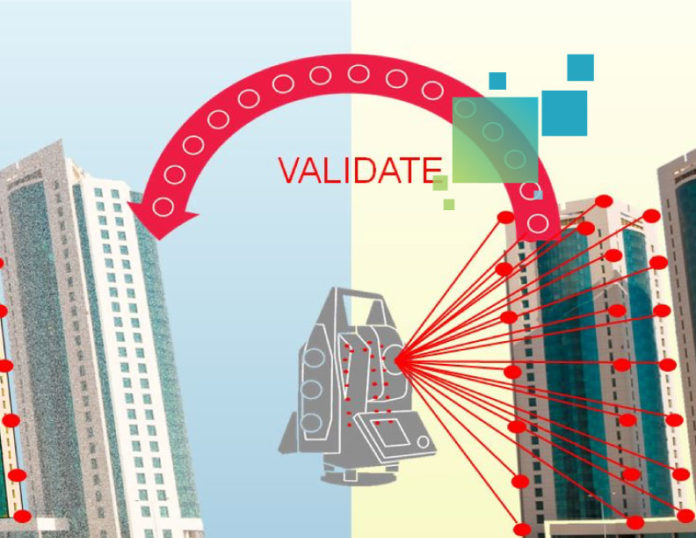

- Validate the construction against the model. Change is inevitable on the jobsite. Formwork for concrete bows, moves or gets kicked, or errors in placement are made. If the structure shifts or changes during construction, then other components such as mechanical, electrical and plumbing systems that are yet to be installed may not fit. One small error can bring the entire construction project to a screeching halt waiting for the right parts to be delivered for rework. Avoiding this situation requires a continuous flow of information from the jobsite back to the office as construction occurs. By capturing the construction in progress using highly accurate multistations, laser scanners or total stations and merging the real-world data with the model data in the office, we can validate the design and resolve potential problems in the office before they become schedule-halting problems in the field, thereby keeping the project on track and on budget.

BIM offers tremendous benefits in construction, but these benefits can only be fully realized if the cycle is complete. By informing, enriching and validating the entire BIM process with highly accurate, real-world data, you can turn your construction models into data-rich, highly intelligent tools that add value at every stage of the construction process and throughout the lifecycle of the asset.