Twenty-four hours – that’s how quickly the WD Partners Field Services group can complete laser scanning and return high-value deliverables to project managers for retail and food service remodels and other architecture, engineering and construction (AEC) projects. It’s a significant improvement over other approaches used to verify existing conditions and produce as-builts with laser scanning, where a project might take several days to scan and another week or more in the office for point cloud processing.

“We’re easily achieving a 60 percent time savings,” said Brandon French, senior reality capture technician. “And we’re able to deliver information the architects and engineers can work from the very next day, which gives them a huge advantage.”

Redefining As-Builts with Point Clouds

The secret to WD’s high-speed scanning operation is a combination of hardware, software and steadfast exploration.

The secret to WD’s high-speed scanning operation is a combination of hardware, software and steadfast exploration.

The firm that describes itself as “thinkers that do™” began laser scanning four years ago with a Leica ScanStation P16 after learning about the potential of the technology at Autodesk University. Working with point clouds was initially daunting, but with guidance and support from Leica Geosystems the firm quickly developed laser scanning expertise. WD soon purchased a second P16 and then a BLK360 imaging laser scanner to add more scanning capabilities to its arsenal. Instead of sending a half-dozen engineers and architects to the jobsite with paper, pencils and tape measures, the company could now send a single technician to quickly and accurately capture measurements in the form of 3D point cloud data for site surveys, mechanical electrical and plumbing (MEP) documentation and other as-built datasets.

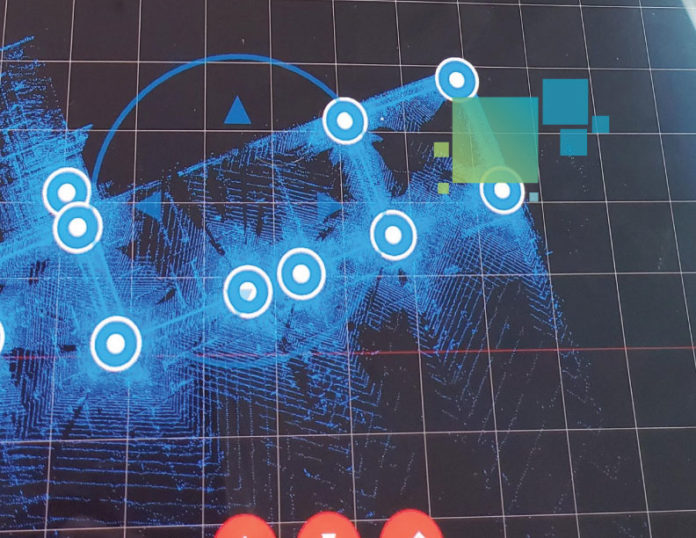

Adding software tools such as the latest versions of Leica Cyclone REGISTER 360, JetStream and CloudWorx further streamlined the team’s workflow by allowing them to quickly load large point clouds and work with the data sets in native CAD environments. With high-resolution 3D data, WD was able to accelerate project completion. It also began gamifying the customer experience and virtually exploring new concepts with high-tech visualization services.

Speed, however, was critical, and the company kept pushing for ways to work faster. When Leica Geosystems introduced the RTC360 in June 2018, which scans at 2 million points per second and enables automated targetless field registration through the application of computer vision and edge computing technologies, WD jumped at the opportunity to be one of the first to try it out. “I didn’t necessarily believe some of the things I saw in the initial presentation,” said French. “But the RTC360 immediately exceeded our expectations in terms of scanning speed and deliverable creation.”

Transforming Turnaround with In-Field Registration

On a typical project, the WD Field Services team captures about 400 to 500 scans. With most laser scanners, the point cloud data from the scans needs to be subsequently aligned or registered in the office before it can be exported to a useful deliverable. Although software advances have made the registration process faster and more intuitive, it still takes time—three to five days of registration is typical for an average-sized scanning project.

On a typical project, the WD Field Services team captures about 400 to 500 scans. With most laser scanners, the point cloud data from the scans needs to be subsequently aligned or registered in the office before it can be exported to a useful deliverable. Although software advances have made the registration process faster and more intuitive, it still takes time—three to five days of registration is typical for an average-sized scanning project.

With the RTC360, most of the registration work is completed as the scans are captured. Through a visual inertial system, or VIS, which uses five cameras or “eyes” and an inertial measurement unit (IMU), the laser scanner is able to “see” its surroundings and produce an accurate station-to-station position in the field. The scanner also supplements the point cloud data with high-quality HDR imaging. As a result, the work required in the office is practically eliminated. “The photo qualities are amazing, and I can register at the same time I’m scanning,” said French. “We still have to put together bundles and coordinate projects, but the registration is at least 75 percent done in the field, which translates into days of work we no longer have to do.”

The time savings from the ultrafast scanning and in-field registration have transformed the team’s ability to deliver valuable information quickly. “I get back, put a couple of scans together and then import that into JetStream and TruView, and it’s done,” said French. “The team onsite doesn’t have to collect their own measurements or wait for the data; they can just keep moving. And with accurate 3D data there are no missed measurements or errors, which eliminates rework. The impact on the overall project is significant.”

Expediting Construction Completion with Comprehensive Information

Architects and engineers on a construction project shouldn’t have to concern themselves with details such as finding the piping and ducts in columns and documenting HVAC components. With the deliverables from WD’s Field Services team, all the information they need is at their fingertips in a digital format. “Using laser scanning and tools like CloudWorx, we can take on most of the work and deliver plans with the full framing structure, full HVAC, full everything,” French said. “It’s a transformational approach.”

As the retail and food service industries look for ways to reinvent the customer experience and compete against online businesses, the ability to quickly complete facility renovations and open the doors is critical to generating revenue. By harnessing the latest advances in 3D laser scanning and pioneering new ways to use point cloud data, WD’s Field Services team eliminates obstacles and expedites project completion. The bar for AEC as-builts just moved higher.

To learn more about using reality capture on your projects, please contact us.