The COVID-19 pandemic has changed nearly every aspect of life, and in the construction space, it is shining a new light on the need for the widespread adoption of technology.

In recent years, changes in profit margin and a shortage of skilled workers have made contractors understandably more cautious about their bottom line. While the industry has adjusted well to the pandemic, contractors remain cautious about the future.

The Civil Quarterly (TCQ), a new publication launched in July 2020 from Dodge Data & Analytics, revealed nearly four in 10 (38%) contractors in heavy construction expect a decrease in their profit margins in the next year. Just 29% expect an increase, a clear indication of the far-reaching effects the pandemic continues to have on the industry.

The likely tightening of belts makes the bottom line all the more critical. Companies no longer have the luxury of excess budget. But, the smart use of technology can help organizations deliver their projects on time and on budget.

One of the most challenging hurdles during the pandemic for owners, designers, and contractors is jobsite access, making it difficult to understand progress and answer questions. But, it lays bare another problem: Organizations need accurate and up-to-date data to make informed decisions.

Project visualization and on-demand feedback is the lifeblood and the foundation of every successful project.

Doing more with less

Even before COVID, the decreased labor force presented organizations with an opportunity to do more with less. But, it required them to rethink how they use technology to amplify their results.

If nothing else, COVID has exacerbated the need to have in place the right teams.

The second quarter 2020 USG Corporation + U.S. Chamber of Commerce Commercial Construction Index found about half (48%) of companies are planning to maintain the size of their workforces for the next six months. Just one in three contractors (32%) plan to hire more workers, while 15% plan to employ fewer people.

TCQ similarly revealed six in 10 (60%) of contractors have a high level of difficulty finding skilled workers currently, and 53% expect the cost of skilled workers to increase over the next six months.

The skilled worker shortage challenges companies’ ability to meet schedule requirements and often necessitates them to respond with higher bids for projects. The old approaches no longer work for the modern workforce, as there is only so much more organizations can ask of their teams before they cannot effectively deliver.

Technology as an advantage

TCQ also revealed the widespread adoption of many advanced tools and digital processes in the heavy civil sector.

Contractors who deploy new technologies onsite cite increased productivity, better ability to manage the project budget and improved safety performance as the top benefits. They need the power to gather measurable data quickly, no matter the situation.

These solutions enable teams to work quicker than they do with manual instruments, allowing organizations to speed up their workflow and avert costly mistakes — from striking underground utilities or digging in the wrong place. Additionally, technology like total stations or GNSS rovers allow a single user to lay out true design objects based on federated and enriched models, reducing the need to deploy large teams, making it perfect for the COVID-19 era or for organizations struggling to find skilled workers.

An accurate representation of the world

Jobsite personnel and machines need to share data and stay synchronized to effectively carry out work on time and budget.

Solutions such as Leica ConX, a user friendly cloud-based collaboration platform, allows companies to manage and share construction and survey data in real-time. With data sharing across an entire construction site, ConX provides real-time project insights to mitigate cost overrun and timeline challenges. Harmonizing and simplifying the data handling for machine control operations also significantly reduces downtime.

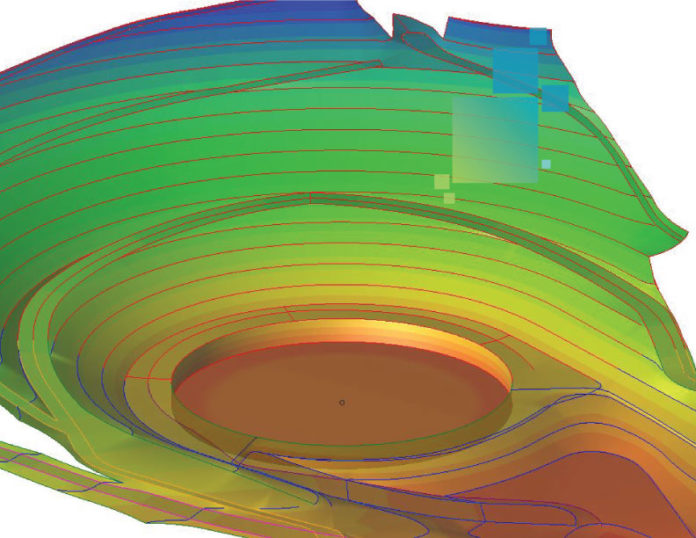

The tool integrates with third-party platforms, enabling teams to share job-related data with all stakeholders. Its simplicity allows non-experienced users to visualize and validate data in 2D and 3D localized on interactive maps.

The ability to share and visualize positioning, reference models and constructed data in real time allows for efficiently monitor productivity, validating work progress, and sharing progress with stakeholders.

With Leica ConX, teams can assign work and provide positioning and reference data to operators and grade checkers to avoid costly rework and errors and validate work has been completed and is to specification.

See more, save time

As projects grow increasingly complex, teams need versatile solutions to promptly implement across diverse environments and on the most complicated projects. They need solutions that allow them to plan, control costs, and complete projects on time.

Smart solutions that are easy to use are the ones that make even the most challenging demands simpler and help solve challenging tasks by making information digitally accessible, infinitely connected and autonomously intelligent.

The construction industry is evolving more substantively and at a quicker pace than at any point in history. Organizations need the tools that empower them to work smarter and more efficiently while not putting their teams at risk or sacrificing quality. Taking this approach will enable organizations to overcome the current environment’s challenges and better prepare them for the next phase of growth.

Troy Dahlin is vice president, heavy construction segment US/CAN at Leica Geosystems, part of Hexagon.