Measure twice and cut once has long been the rule of thumb in the mechanical, electrical and plumbing (MEP) industry. But what if you don’t have time to measure twice? Or even to measure once?

With efficiency and accuracy increasingly under pressure, MEP companies are turning to laser scanning.

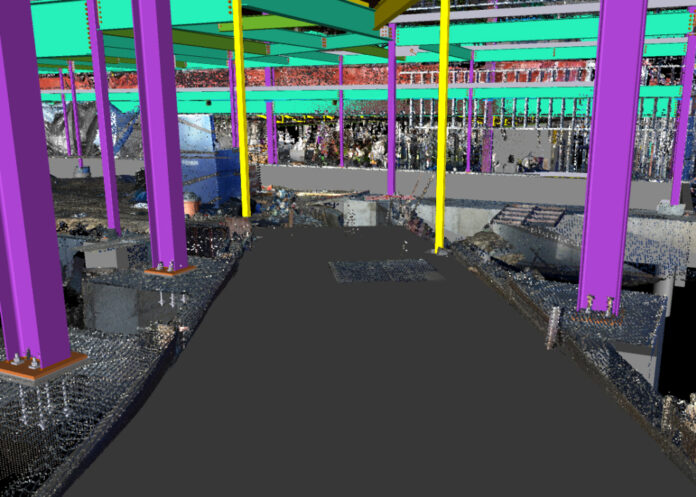

UMC, a full-service MEP contracting company based in Washington state, has gained significant benefits from laser scanning.

While UMC has been working with 3D applications for more than 25 years, its decision to invest in a digital measurement tool was born out of necessity. The day of reckoning arrived after completing a grueling boiler room upgrade for Boeing, which required the fabrication of thousands of spools.

Ryan Hoggatt leads the company’s manufacturing unit, which is primarily focused on prefabricating assemblies for mechanical and plumbing applications, such as spool components.

“I basically said there’s got to be a better way than tapes and lasers,” explains Hoggatt.

The company invested in a Leica Geosystems laser scanner and immediately saw the value.

Accuracy

“Being able to scan into a BIM model and then draw the piping knowing it will fit in the field with certainty is huge for our clients,” says Hoggatt, who now runs UMC’s reality capture group.

UMC’s fab shop quickly came to rely on the reality capture group for 100% accurate parts specs.

RELATED: Discover 5 ways to survive and thrive in a BIM-enabled environment as an MEP contractor >

Speed

Time savings is another significant advantage of laser scanning.

“We were working on a clean room facility that was modeled for miles and miles of under-floor piping,” Hoggatt says. “They initially wanted us to hand draw the detailing because of a schedule issue. That would have taken hundreds of hours. Our operator went out and scanned the floor and brought the data back. We accomplished in less than a week what would have taken at least a month. All in 3D, too. Now the client wants the entire facility scanned.”

Improved Communication

Being able to see the project in 3D creates a better understanding among key stakeholders. When challenges arise, the visualizations generated with the laser scan data makes communication easier and improves problem-solving.

Increased Safety

Since laser scanners capture accurate, comprehensive data from a distance, workers can typically get all the measurements they need from safe locations on the ground.

A Better Value

With digital precision and integrated models, UMC has increased project accuracy and quality while driving down costs. Having a progressive 3D model helps teams identify errors that would easily be missed with manual measurement methods. The ability to proactively eliminate surprises enables the company to save its clients time and resources.

RELATED: Read how UMC used laser scanning to quickly capture every inch and angle of a complex space to reproduce intricate surface details >

NOTE: This article originally appeared in the Eguide: 5 Ways MEP Contractors Can Survive and Thrive in a BIM-Enabled Build Environment. Download your Eguide here >