It’s no secret that utility strikes pose a threat to utilities and the contractors tasked with completing their projects. According to the latest DIRT Report (Damage Information Reporting Tool) in the U.S. in 2022, reports of a line strike happened more than 500 times each day. The costs to stakeholders are staggering, involving millions of dollars in damages, project delays, injuries and loss of life.

Reducing utility strikes was the initial target of Brasfield & Gorrie’s Innovation Department when looking for new ways to deploy GIS (Geographic Information Systems) technology to improve operations. For the large, privately held contractor, safety was a logical place to start. “Utility strikes are a big problem in the construction industry,” says Kyle Duncan, innovation and operations technology specialist for Brasfield & Gorrie.

The traditional method of preventing utility strikes involves the use of a dig board – a 3-foot x 4-foot paper posted on a plywood board which shows every utility on the jobsite under construction. “The problem is the board isn’t really helpful for someone a hundred yards away who needs to remember where the utility line is,” says Duncan. Also, over time utility lines initially located by an 811 service would fade, requiring additional expense to mark the utilities for a second time.

With the use of smartphone GPS, Esri GIS mapping software and QR codes, Brasfield & Gorrie transformed the plywood dig board into a digital dig board that is always available via an app on an employee’s cell phone. It was a significant improvement. But Duncan and Ryan Hittie, Brasfield & Gorrie senior innovation and operations technology specialist, saw an opportunity to take the concept even further.

“Our next step was determining how to get accurate data collection in the hands of our field personnel so we can collect reliable location data on every utility we put in the ground.”

“The GPS on employee cell phones was only accurate to about 5 to 15 feet on a good day,” says Duncan. The company wanted more accuracy. They also wanted more data.

“We have over 200 projects in the company, and we have about 70 field engineers,” says Duncan. “Our next step was determining how to get accurate data collection in the hands of our field personnel so we can collect reliable location data on every utility we put in the ground, not just what our field engineers can capture with their total stations.”

Easy High-Accuracy Asset Data Collection

The solution would need to be easy to use with minimal training by project managers, superintendents, interns, safety managers and other field personnel. It would need to integrate easily into Brasfield & Gorrie’s existing workflows, including a seamless interface with Esri ArcGIS Field Maps. Ultimately, it would need to enable the company to maintain comprehensive, accurate, living documentation on every utility installed in the ground for reference on future projects and owner asset management.

“The FLX100 plus GNSS technology is giving both the owner and our field teams the tools to make decisions ahead of time and in real-time.”

Duncan decided to implement the Leica Zeno FLX100 plus GNSS smart antenna, which provides 1-2 cm accuracy and can be paired with any Android, iOS or Windows smartphone or tablet for a bring-your-own-device approach to field data collection.

The smart antenna met all the requirements established by the team. It is also lightweight with an extensive battery life. With the Leica Zeno Connect app, users can stream high-accuracy GNSS positions from the FLX100 to third-party software, including Field Maps.

How It Works

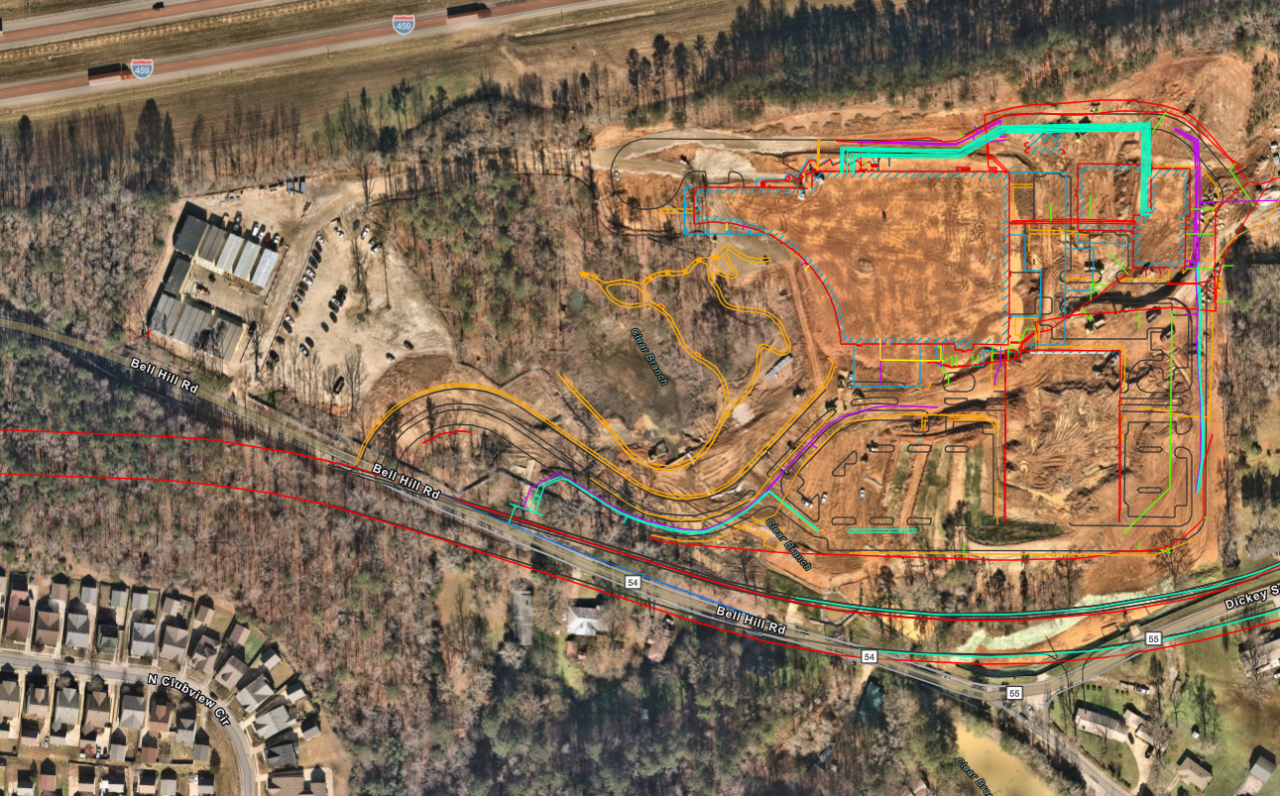

For Brasfield & Gorrie, the process begins with gathering traditional civil survey files or documentation from the company’s civil engineers and entering them into Esri ArcGIS Pro software. On the jobsite, field personnel scan a QR code to open the map for the right project. The GNSS smart antenna picks up the satellite signal, and the Leica Zeno Mobile app configures the GNSS, connects to the RTK network and makes a real time correction for 1-2 cm accurate location data.

“The ArcGIS Field Maps app opens the map, and employees can quickly see all the utilities around them,” says Duncan. “Our field workers can now make real-time decisions based on accurate information.”

Accurate Digital Documentation Saves Time and Money

In addition to helping prevent utility strikes, the system makes it extremely easy to accurately record the location of new utilities installed. The ease of use of the system enables the team to get accurate as-built data affordably. No special skills are required.

“You cannot expect to pay a surveyor to sit around and wait for every piece of infrastructure to be put in the ground just to record its position,” says Jason Hooten, GIS sales & support manager with Leica Geosystems, part of Hexagon. “There are sometimes long delays between each installation, and it isn’t practical. You need to empower field workers to collect data onsite while the line is exposed.”

Brasfield & Gorrie trains users on the device within an hour and a half in the field. “With the Leica equipment and Esri Field Maps software being so simple and intuitive, there aren’t any issues,” says Hooten. “It’s made to collect data and deliver that data back to the mapping system in a very streamlined workflow. That enables people who are not surveyors to collect data easily and at a much more affordable rate, while freeing up surveyors to do tasks they are required to perform and do them more effectively.” Setup takes seconds compared to a total station, which can take 15 minutes or more to set up.

After the data is collected, it’s pushed live to the digital dig board in real time. “We’re no longer waiting for the data,” says Duncan. In the past, with field engineers collecting data using total stations, it could take up to 24 hours to update the digital dig board. “It would require a middleman like myself to take the DWG file and update it on the map,” adds Duncan.

The client’s map can also be updated in real time with the data from the GNSS smart antenna.

As a long-time user of Leica total stations (Brasfield & Gorrie owns 70 Leica iCON total stations), Duncan appreciates the reliability and accuracy of Leica equipment and believes Leica’s reputation helped build trust in the Leica FLX100 plus GNSS smart antenna technology.

“We knew it would work,” says Duncan.

High Value Asset Management

Accurate documentation is important to project owners and contractors for success on future projects. “We want to have good living documentation of what’s in the ground for the future,” says Duncan.

In the past, the location of utilities might have been based on measurements of a physical feature, such as an offset to an edge of a pavement that could potentially be moved or even removed. According to Hooten, using GNSS data to record as-builts means they will always be accurate.

Digital documentation is also helping Brasfield & Gorrie deal with utility lines that interfere with project plans. On one project in South Carolina, a worker using the FLX100 plus discovered a fiber line where a footer was supposed to be located. “Before we had this tool, we wouldn’t know about this line until we started digging the footer. It would have delayed the project,” says Duncan. “The technology is giving both the owner and our field teams the tools to make decisions ahead of time and in real-time.”

Scaling Up for Greater Impact

Since starting the program two years ago, Brasfield & Gorrie has created more than 100 digital dig boards, with one in every sector of the company’s business. The increased accuracy and data collection efficiency from the GNSS smart antennas is having an impact. “We have had a significant reduction in utility strikes on the job sites where the digital dig board has been deployed,” says Duncan. Sixty Leica FLX100 smart antenna units are currently in use, and an additional seven units were recently ordered.

According to Duncan, there was minimal resistance to the technology when initially deployed. Since most everyone on the jobsite has a smart phone, there was a low barrier of entry. Before deployment, Duncan worked with his local Leica dealer Transit & Level to test a unit against a total station with a field engineer. “Once we tried it out on a couple of jobs, usage expanded by word of mouth,” says Duncan.

As a long-time user of Leica total stations (Brasfield & Gorrie owns 70 Leica iCON total stations), Duncan appreciates the reliability and accuracy of Leica equipment and believes Leica’s reputation helped build trust in the Leica FLX100 plus GNSS smart antenna technology. “We knew it would work,” says Duncan.

Expanding Usage of GIS in Construction

While GIS has been used to map utilities for two decades, in the last five years usage among contractors has grown. A 2020 report from Dodge Analytics in partnership with Esri and Autodesk, found 97% of general contractors surveyed had used GIS for site data collection, with 44% using it on more than half of their projects. “Esri has started addressing the AEC market, and contractors in engineering houses are starting to see the value of GIS,” says Hooten. “It can be the hub of all their data.”

“Brasfield & Gorrie is at the forefront of adopting GIS technology for construction,” Hooten adds. In addition to using the technology for locating utilities, they have expanded their usage to include as-builts and more effective project management.

“People often don’t understand what the technology is capable of doing until they get it in their hands,” Hooten says. “And then once they apply it to specific tasks, they start realizing all the benefits.”

Interested in learning more about utility detection and mapping for construction? Get in touch with a Leica Geosystems asset management specialist to discuss your needs.