In the fast-paced world of MEP construction, you’re expected to design and deliver building systems that run flawlessly from day one. Using building information modeling (BIM) software to create 3D models that show what and where components and equipment belong in a project can help you meet these goals quickly and efficiently. In fact, an estimated 80% of MEP engineering firms use BIM technology on at least half of their projects, according to a Dodge Construction Network study.

By using a laser scanner along with your BIM platform, you can coordinate your project scope with the general contractor and automate tasks that would take hours or days to complete manually. These tasks include documenting existing infrastructure, sizing and laying out new components and equipment, and running deviation checks between as-built construction and your design for quality control.

Here are five steps to leverage 3D reality capture technology and BIM to optimize your workflow and increase your profitability.

1. Start with accurate laser scan data

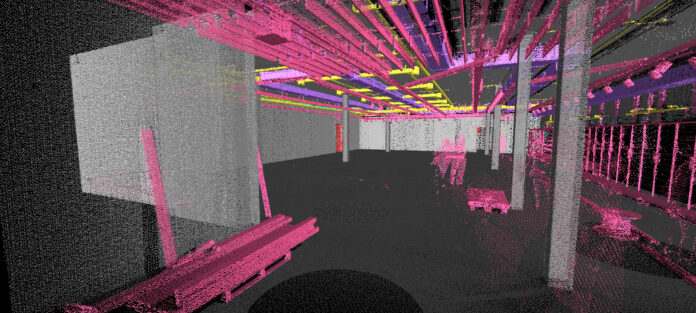

To kick off a project with an understanding of its true conditions, use 3D reality capture technology to create your own BIM, particularly if the supplied BIM was not created with a recent laser scan. For retrofit projects, you will need to understand the existing MEP infrastructure at a level of detail and tolerance that cannot be captured efficiently by manual means. With laser scanning, you can quickly and safely generate a comprehensive point cloud of measurements that will serve as an accurate and visual reference for creating a BIM.

Be aware that not all laser scanners are equal. Use technology that is known for data quality and accuracy, such as Leica Geosystems laser scanners, to give you a solid foundation for your design, fabrication and installation needs.

2. Use software to automate point cloud registration and conduct advanced analyses

Laser scanning can capture upwards of 2 million measurements per second, but that’s not the only process that can happen quickly with optimized scan-to-BIM and BIM-to-field workflows. Digital features available in the scanner hardware itself can aid your workflow by guiding your site capture, alerting you to errors and advising if, for example, you’re missing a scan position. You can also leverage downstream software that draws on the power and speed of artificial intelligence to auto-register your point clouds, auto-mesh them for clear and fast visualizations and clean up data artifacts and moving objects caught in the scans.

Leica Geosystems’ enterprise-level data management and collaboration tools allow you to grant access to your point cloud visualizations through a basic web browser. The tools can also automatically classify common 3D surfaces, such as walls and doors, identify pipes and pipe runs, and run clash detection checks.

3. Maximize the compatibility of your files

Make sure you have the ability to publish point cloud data in industry standard formats, such as E57, LAS, LAZ and PTF, as well as file types compatible with popular BIM software, such as Autodesk Revit. Your software should also help you compress large amounts of data into small files sizes to minimize computer processing times.

4. Extend your capabilities with software plugins

Beyond the basic capabilities of software, you can use plugins to open your optimized point cloud files in your CAD and BIM programs of choice. Leica Geosystems offers several CloudWorx plugins for popular third-party software.

5. Roundtrip your data from BIM to the field and back

With your BIM in hand, you can make sure construction proceeds as designed. Take your model into the field and align it with the on-site control points using a total station or multistation. Use your laser scanner to capture construction progress and then bring that point cloud to the office for comparison against your BIM. Leica’s advanced software solutions can automatically detect and heatmap deviations between as-built work and the BIM. If the changes are deemed appropriate and acceptable by your team, the software can even push the updates back into your BIM. The result is a BIM that maintains its accuracy throughout construction and can be easily handed off at closeout.

With Leica’s hardware and software solutions, you have access to advanced technologies that enhance and expedite your BIM-enabled workflows while minimizing the risk of errors and rework.

To discuss your needs with a building construction specialist, contact us.