What if there was a way to see potential problems on your building construction projects before they occur – a simple tool that instantly gave you comprehensive, accurate information so that you could quickly analyze existing conditions and avoid errors? How would that capability transform your work?

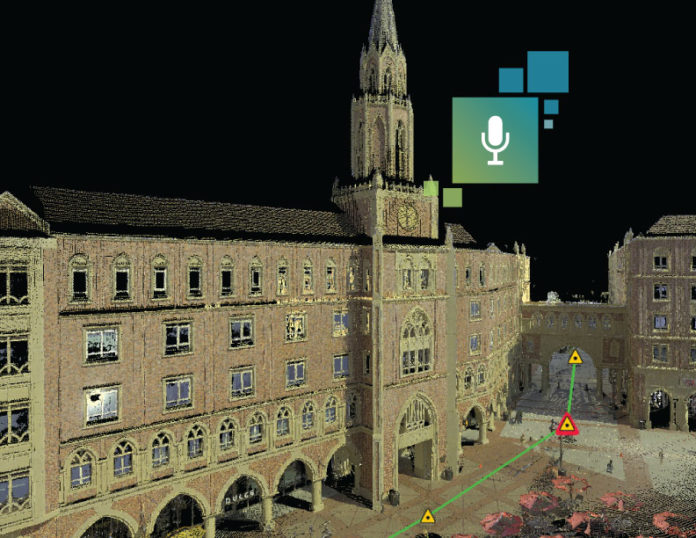

3D laser scanning reality capture provides that insight, and the latest innovations from Leica Geosystems, part of Hexagon, make it fast and easy to integrate laser scanning into your existing building construction workflows. In this podcast interview, Clair Vander Zwaag, Building & Construction Reality Capture Manager for Leica Geosystems, shares how laser scanning helps contractors avoid rework and maximize productivity. He also provides keen insight into how the new Leica RTC360 solves many of the challenges of using reality capture in building construction. To learn how 3D laser scanning can benefit your projects, contact us.

—— FULL TRANSCRIPT ——

Host: Give me a brief history of Clair Vander Zwaag and how you wound up at Leica.

Clair Vander Zwaag: Basically, I spent about 15 years with a civil survey firm back in the day practicing CAD, project management and civil engineering. One day the firm I was with approached me and said, “Hey, we’ve got this Leica scanner. We need somebody to start working with it to make some money with it, and we think you’re the guy.” So, instead of working on rims and inverts and everything underground, I had the opening to go into collecting geometry above ground. I thought that was pretty cool. These days, I’m working with engineers and contractors and architects who self-perform with laser scanning.

Host: Can you tell me a little bit about Leica Geosystems? It’s fascinating to me.

Vander Zwaag: Leica Geosystems has been around for about 200 years. The company is a leader in terms of innovation. They’ve come a long way with geomatics, going all the way back to World War I and World War II where they started with surveyors and leading up to today, where they bought the first laser scanning technology and now have moved that technology forward. It’s exciting to be a part of a reality capture team with so many different solutions that Leica Geosystems is bringing to the table.

Host: You know, you had the opportunity, as you mentioned, of working in the field with Leica systems and being able to come up out of the underground, so to speak. The concept that you just mentioned of reality capture – that’s really at the heart of what Leica is trying to do with regard to the AEC industry, right? Reality is of the utmost importance in being able to capture and use that information in its purest form. That’s really what Leica is all about.

Vander Zwaag: It truly is. It’s collecting geometry from the field and using it to not only to make money, of course, but to maximize efficiencies. We want to make sure people are smarter and making smarter decisions. And of course, utilizing the greatest and latest technology. Going back to the original question about Leica – Leica is so well established and respected in the industry. When you hear that name, it just sparks interest in technology and wisdom and so many years of great performance and growth.

Host: One of the things that impresses me about the way Leica approaches its corporate existence is Leica appears to be always trying to create something new. It’s almost like you’re trying to put yourself out of business because you’re trying to create new products. And the weird thing is it doesn’t appear that Leica creates products to generate sales. You genuinely create tools and processes and technology with an eye toward, as you mentioned, helping customers succeed. It’s not so much about selling the apparatus as it is the great things the apparatus can help the customer do. Tell me a little bit about that.

Vander Zwaag: There’s really a lot that can play into that – maximizing productivity, avoiding rework, change orders. The proactiveness of the engineering team and leadership and the way we’ve listened to our customers is very important. As a customer myself, I always felt I had a say. As I was going through workflows and talking about some of the issues and troubles that we had back in the day, there was always an ear, and I think that’s what Leica is very good at. Turning that around now and creating state-of-the-art solutions and perhaps going above and beyond with those solutions is typically what it’s all about. And in the last couple of years we’ve certainly seen that with some of the offerings in reality capture, which I’m sure you’re interested in.

Host: I am. I want to lead into that by talking about your background just a moment. And that is you were one of the early adopters with regards to laser scanning. You were really on board and that interested you from the beginning. What about that technology captured your imagination? Why was it so important to you to see that technology succeed?

Vander Zwaag: Back then it was so new, and just going out and showing it off was a big thrill. It’s definitely got the cool factor. But on the other hand, it’s got a purpose and to share that purpose and that technology really opened eyes wherever we went. I remember one of the first laser scanners I ever worked with actually shot 3000 points a second, and back then to do a full 360-degree scan, it took an hour and a half to two hours to collect this information from one position. Nowadays we’re doing it rapidly, at 2 million points a second. It’s just insane to think about how quickly that technology has progressed.

Host: So let’s do a comparison. We talked about, as you mentioned, capturing 3000 points a second. Bring me to… I would say bring me up to today, but you’re actually living in the future. Bring me up to the RTC360 and explain to me just what a quantum leap this is as far as a functional tool.

Vander Zwaag: The RTC360 – when I saw this thing for the first time, I knew it was a massive game changer. Going back to those first days and what we had to go through just to set up a scanner and level it and get it going versus today, where we just pop in a couple of batteries and fire this thing up. It’s a seriously powerful laser scanner in a compact design. A few points about the RTC360 which really sets it apart in the industry is that it’s easy to use, it levels itself, and it’s an instrument that you can learn in 10 minutes and you’re going to remember two weeks later, which is huge. What we’re seeing already with this type of device is pretty much anyone can use it, from project managers to VDC personnel or even interns, and go out to the field and capture reality.

Another capability is that capturing imagery is fast with full HDR. We’ve never taken pictures in less than five to 10 minutes, and now we’re doing it with a scanner in one minute which is a huge, huge increase in productivity. Another feature is that it’s smart – it literally tracks its own movement when you’re on the site, so the need for targets, spheres and even survey control, a lot of that is eliminated now with what we’re calling VIS, which is the visual inertial system. This a real-time tracker; it registers itself on the fly. What we’ve done in the office in the past as a completely separate process is now being eliminated with that scanner in the field. And like I said earlier, it’s ultra fast. It picks up data at 2 million points a second. So you’re not going to miss any details.

Host: Is this something you guys have been thinking about for awhile?

Vander Zwaag: I believe it’s been in the works for awhile. It’s certainly a cutting edge advancement that’s never been seen. This particular scanner literally has five eyes, and every time you pick it up to move it, it’s tracking your movement and it understands where you are positionally related to the previous scan. So in terms of the way we operate when we’re doing our scans in the field, it really changes our whole workflow and our mindset in terms of productivity and speed, and that really translates into precision, accuracy and everything else that goes into the processing to deliverables at the end.

Host: Now, this is an incredibly advanced technology, but you mentioned that it’s not hard to learn and it’s easy to deploy. So let’s talk about it. I’m a contractor and I’m really interested in getting into reality capture. I feel it’ll help my business really grow and help me give better service to my customers. So how do you help me decide how I approach this process? Because this kind of technology, I would imagine, can be a little overwhelming.

Vander Zwaag: The first time you take a look at it, it certainly can be overwhelming. What I remember back in the days when I was a customer, and even now working with folks, is that we really want to understand your needs, what you’re looking to do with the technology and how you want to get there. We want to look at the types of issues or problems you may be having or even the projects or deliverables you want to achieve with a scanner. There are a few different factors that go into it, including ranges and accuracies, and certainly project size could be a big one as well. So what really sets Leica apart also is the opportunity to work with somebody who’s skilled with the applications, with the hardware and software, and is able to put a true package together which is going to fit exactly to your needs and where you want to take the technology moving forward.

Host: It sounds like the word of mouth or mentorship of someone who is already successfully using this and has already integrated it might be something that would be beneficial to a contractor that’s not as tech savvy as they would like to be.

Vander Zwaag: It really is. Often if any questions like that that come up, I’ll ask the person to get online in a forum and check with other professionals in the industry who are experienced. But I think it’s a real edge for them to be able to lean on somebody who’s perhaps been there and done it, whether it’s somebody that works for Leica or not, to be able to answer those questions quickly and effectively and to be proactive in their solutions and experiences.

Host: It sounds like you’re genuinely concerned about the success of every contractor’s project, whether you know them or not. You just hope, Oh man, I hope they’re doing this or I hope they’re self-performing floor flatness, or whatever. What trends have you seen as someone who has that contractor’s mindset? What trends have you seen within the last year or so in the industry that really caught your attention as far as thinking, This might change the industry a little bit.

Vander Zwaag: There are a few different trends that we’re seeing out there right now. First of all, comparing or QC against design models with scan data to make sure things are built correctly is an easy one that’s being done all the time. It’s a validation piece within the process. A lot of GCs have adopted that process, and they’re very good at it. Another trend is floor flatness or floor levelness. There are now applications and software processes that kick out real time dynamic floor flatness/floor levelness reports along with sort of like a heat mapping of the pad itself. It’s actually elevation mapping. It’s exciting to see real-time capture and to be able to make real time decisions. Another one that comes to mind is the ability to coordinate on a point cloud. In years past, we used to spend a lot of time taking point clouds and mapping them up, or in other words we 3D modeled them, whether it was AutoCAD application or a Revit application. I see a lot of folks now using the point cloud itself and not spending time to model. They’re using the point cloud to clash detect and coordinate their BIM models and their processes for validation moving forward.

Host: So even with all of these innovations … what do you think is the next challenge? What is still a really difficult problem you have to figure out about reality capture?

Vander Zwaag: That’s a good question. It’s fun working with a lot of very smart people all around the country, and they are constantly pushing the envelope and trying new things. It’s challenging not only for them but for the rest of us to make sure they’re equipped properly with the right workflows, and also to listen to them and help them be cutting edge, whether it’s a simple process or putting together a few pieces. Along that line, I think the software is really starting to integrate or blend together. In years past, when I started [laser scanning], we were gunslingers and mavericks. To figure out how to get a 3D model of a piece of iron or pipe, we had to use all kinds of different software platforms to do it. Nowadays, Leica is very well known for integrated workflows, where you don’t have to go out and buy three other pieces of software to get one thing done. The RTC360, I think, is a truly amazing fusion of where this technology is going, and it’s exciting to see what the future holds.

Watch this video to learn how the RTC360 can boost ROI by 40% or more.