Leica Geosystems recently released iCON build v8.0, the latest update to the popular construction software for layout, as-built and verification tasks. The new release adds tools that deliver even greater efficiency on the jobsite and in the office.

Here are six important new capabilities and how you can take advantage of them.

Enhanced Prism Tracking: A Valuable Timesaver

iCON build v8.0 introduces active prism tracking that continues in the background when you switch applications. You can seamlessly navigate through different functions without the need to constantly restart tracking.

This reduction in button presses to resume tracking saves time and simplifies the user interface. You can focus more on your measurements and less on navigating the software, leading to a more efficient and user-friendly experience.

Additionally, if you’re using the Leica AP20 AutoPole, with built-in tilt compensation, iCON build v8.0 maintains tilt initialization even when changing settings or functions.

“Ultimately, everything hinges on production efficiency,” says Keith Lantz, iCON sales training specialist for Leica Geosystems. “The time you invest in focusing on the prism, tracking, and setting up points is substantial. The new software update will enable you to avoid constant re-initializations. It’s not only about the prism itself but also about optimizing the initialization process of the AP20. This significantly enhances productivity in the field.”

Jeff Gerber, senior central support specialist for Leica Geosystems, agrees. “It’s nice that you don’t have to keep hitting the start button to get it measuring again,” he says. “It just keeps measuring and tracking while moving between the apps.”

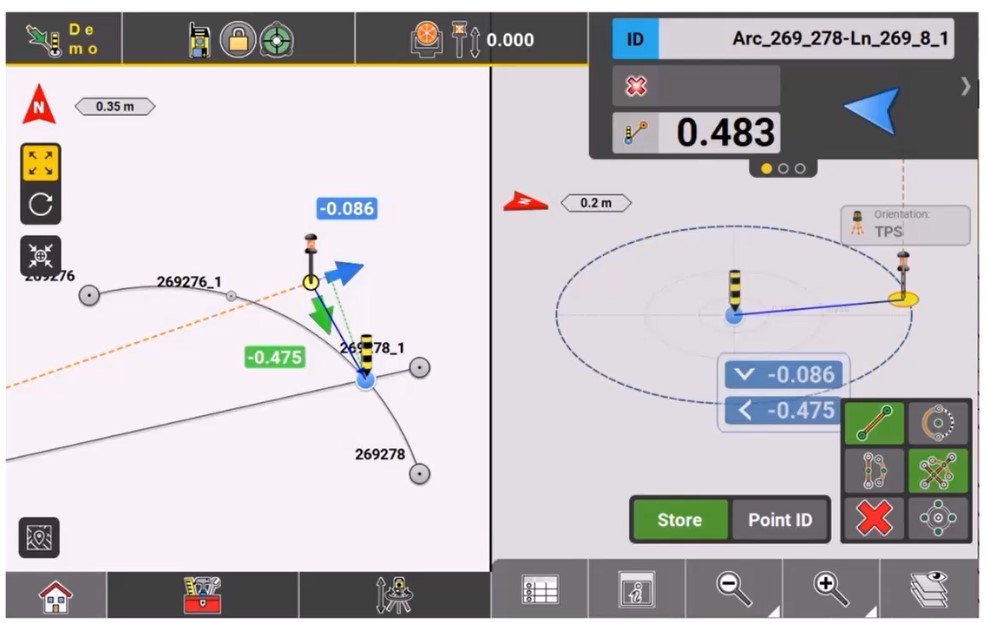

Auto-Snap Improvements: Better Onsite Control with Safety Benefits

iCON build v8.0 features improvements in the auto-snap capability. Auto-snap allows you to lay out points directly from CAD and IFC elements. Now, the feature works effectively when the setup is in 2D with 3D data, as well as when the data is only in 2D.

When auto-snap mode is activated, the software now automatically switches to a split-screen view and selects the next point as the dynamic point. As you move around the site, the software provides relevant points without the need for repetitive manual selection, saving time and reducing errors.

“This update is about empowering field workers to be more efficient and to have greater command over their tasks,” says Lantz. “Should there be any missing data in the CAD file, it provides them with the means to continue their work seamlessly, without the need to revert to CAD specialists. Field teams are equipped to manage everything independently onsite with a method that is both straightforward and simple.”

The update also provides an important safety benefit. “It’s hard to enforce a requirement to wear gloves when everything is a touchscreen,” explains Nate Bush, iCON sales engineer for Leica Geosystems. “Automating the point selection for layout makes it easier to get the work done with the gloves on.”

Tolerance Settings and Standard Deviation: Enhanced Flexibility and Precision

iCON build v8.0 allows you to change tolerances directly during the setup wizard instead of needing to exit the setup to change tolerances. Plus, iCON v8.0 displays a single standard deviation value for both 2D and 3D setups.

By providing immediate feedback on the quality of the setup based on standard deviation points, you can quickly discern whether an issue lies with the tolerance settings or a specific point. iCON v8.0 also offers three preset setup tolerances and four user-defined setup tolerances, allowing for a high degree of customization. This flexibility caters to the specific needs and requirements of different construction projects.

Lantz says, “As someone who visits various job sites with distinct tolerance requirements, I often encounter a challenge. If I forget to adjust the tolerance settings, I find myself having to leave the site to reset and input the new tolerance parameters, followed by setting up everything again. However, with this new method, I can directly make adjustments from the screen, altering the tolerance settings on the fly.”

Formwork Deck Mode: High Productivity in Dynamic Environments

iCON build v8.0 introduces a new formwork deck mode, allowing you to work in unstable working environments, such as wooden formwork decks. These decks often experience movement and instability, especially when multiple people are working on them, which can temporarily throw instruments out of level.

Formwork deck mode addresses this issue by allowing the instrument to automatically resume measurements once it returns to a level position, without the need for manual intervention. This mode is particularly well-suited for MEP and HVAC layout crews who often work with large objects over short distances. In such scenarios, the slight deviation in measurements due to temporary leveling issues is usually acceptable.

Lantz says, “Buildings move; they shake and rattle. This tool provides you with a means to continue working, even if it means compromising slightly on accuracy. It keeps operations flowing. For tasks that don’t demand absolutely high precision, it’s an excellent resource because it ensures that the work doesn’t come to a halt for typical movement.”

IFC Visualization: Enhanced Clarity and Detail

iCON build v8.0 includes enhanced visualization capabilities for IFC data and objects. In addition to maintaining the default shaded visualization from previous versions for basic renderings, iCON build v8.0 adds three new visualization options: a shaded display with visible edges, an unshaded wireframe with all lines visible, and a wireframe in perspective view with hidden lines.

By selecting the most appropriate visualization, you can more easily identify specific architectural or structural details, such as steps in slabs or junctions between walls with edge lines. This aids you in precise planning and execution of construction tasks.

“Slabs that are displayed in a uniform color in an IFC can make it difficult to distinguish depressions and steps,” explains Bush. “The improved visualization capabilities in iCON build v8.0 enhance the visibility of edges, allowing you to quickly identify changes in the slab’s level from a plan view. It really makes the edges pop.”

Site Control: Enhanced Accuracy and Confidence

iCON build v8.0 includes a new licensed site control application that allows you to apply a polygonal method to check primary and establish secondary control points. This method is akin to a traverse, making it especially useful for when you are verifying and setting up control points.

The app guides you through a workflow that involves the “2face & set” function, enhancing the ease of use, even if you don’t have extensive surveying experience. The app is particularly valuable for achieving high accuracy rates, especially for secondary control points at longer ranges.

Lantz says, “This feature enables you to conduct your own check-ins, verifying your primary control and establishing secondary control with a higher accuracy rate than previously possible. By providing a function similar to a traverse, you can verify new or existing points for accuracy at extended ranges.”

To explore digital layout solutions and discuss your needs with a building construction specialist, contact us.