Meeting tight flatness requirements on poured concrete slabs and decks is a challenge, and accelerated project schedules leave little room for delay. Traditional methods of quality assurance only detect flatness problems once the curing process is well underway, often leading to corrections that are unsafe, messy, slow and costly.

Laser scanners, capable of gathering accurate, three-dimensional data at the point of construction, have become an increasingly popular alternative in the construction industry over the last few years. In the past, in-field scanning workflows were considered too slow and cumbersome for an active construction site, with data collection taking several minutes. The revolutionary speed of the Leica RTC360 laser scanning solution changes that equation, with accurate data acquisition in as little as 26 seconds. Combined with the fast data pipeline provided by Leica JetStream, reality capture data is ready for processing almost as soon as it’s collected.

The advances recently attracted the attention of StructionSite, an industry-leading 360 photo and video documentation platform. StructionSite and Leica Geosystems, part of Hexagon, have begun collaborating to create workflows that combine the speed of the Leica RTC360 solution and the simple Minimum Viable Workflow™ approach pioneered by Rithm, part of StructionSite.

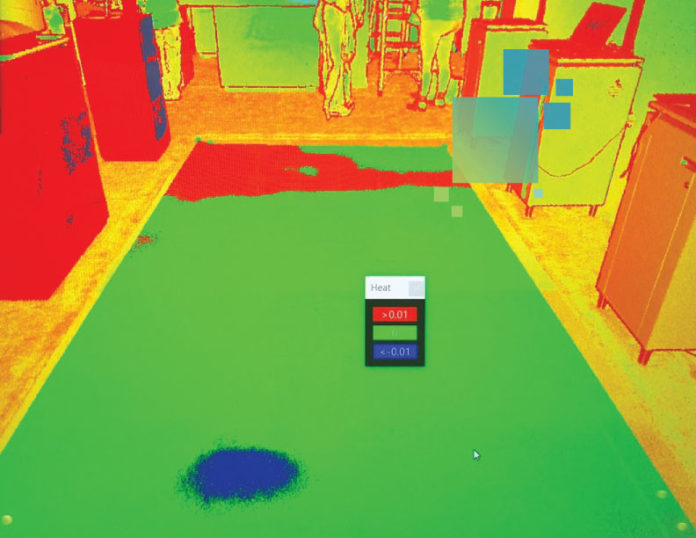

The first result was an exceptionally fast wet-concrete deliverable produced using the Leica RTC360 3D reality capture solution and the Rithm App powered by JetStream to produce a heat map in the field. The app is currently in preview mode. If you’re at World of Concrete, come check it out at the Hexagon booth, C4852, or contact us for more details.

Stay tuned to see how we advance reality capture workflows together!