If you’re familiar with machine control technology but haven’t employed it yourself, here are some tips to help you move forward.

1. Assess the benefits

Machine control offers a number of benefits, but perhaps none more important than improving the skills of inexperienced operators. You won’t have to worry about rework or operators who take too long to complete a job. In addition, with a Leica rover, your team can get to work laying out all the elements of the jobsite without waiting for a surveyor to show up. Even a simple job like digging a foundation for a house can benefit from machine control. You won’t need a person to jump down in the foundation area to check the grade again and again. The technology tells the operator where to dig and frees up the grade checker to work on something else.

Machine control can lower your construction costs significantly. In addition to reducing surveying costs, jobs are completed faster and more accurately so that means less spent on equipment and people. Equipment maintenance costs are reduced because automation leads to less wear and tear on the machine.

Concern for worker safety is always at the top of your priorities, and with GPS technology, fewer people are required on the jobsite so that means less people placed in harm’s way. Fewer surveyors, due to far less staking and fewer civil engineers, grade checkers and project managers, because technology allows them to remotely transfer grade control data, 3D models, and more from the jobsite to the office.

2. Test the waters

The technology required for machine control requires a financial investment, but don’t let that discourage you from trying it out. You need to see the benefits of the technology for yourself. There are numerous ways to test machine control without committing to a purchase. First, you can contact a Leica dealer for a demo.

Rental is also a great way to test the waters. Consider a short-term rental or rent-to-buy arrangement. With a rent-to-buy option, if your project lasts three or four months you will have almost 40% of the technology paid for. Most rental companies will apply 80-100% of your rental payments toward a purchase.

The return on investment for machine control is easy to see. You will complete jobs faster without any rework and your 3D system will pay for itself in the first year if you’re using it on all your projects. Run your numbers on this ROI calculator. I find about 99% of contractors who demo or rent the technology for a month move forward with a purchase.

3. Start small and grow with the technology

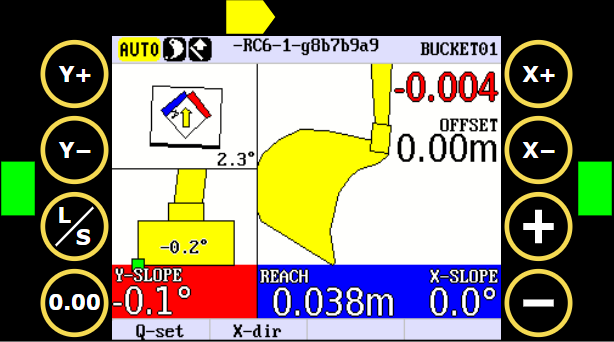

While you can use 3D technology on every job, sometimes 2D control systems can work well at a lower price point. A 2D system shows depth and slope but won’t tell you where you are on the job. It uses laser technology to reference benchmarks throughout the excavation process. 2D systems work best for simple projects. For example, a septic tank company that digs nearly the same profile on every job can use a 2D machine control to increase speed and accuracy, and they may also be able to eliminate a grade check.

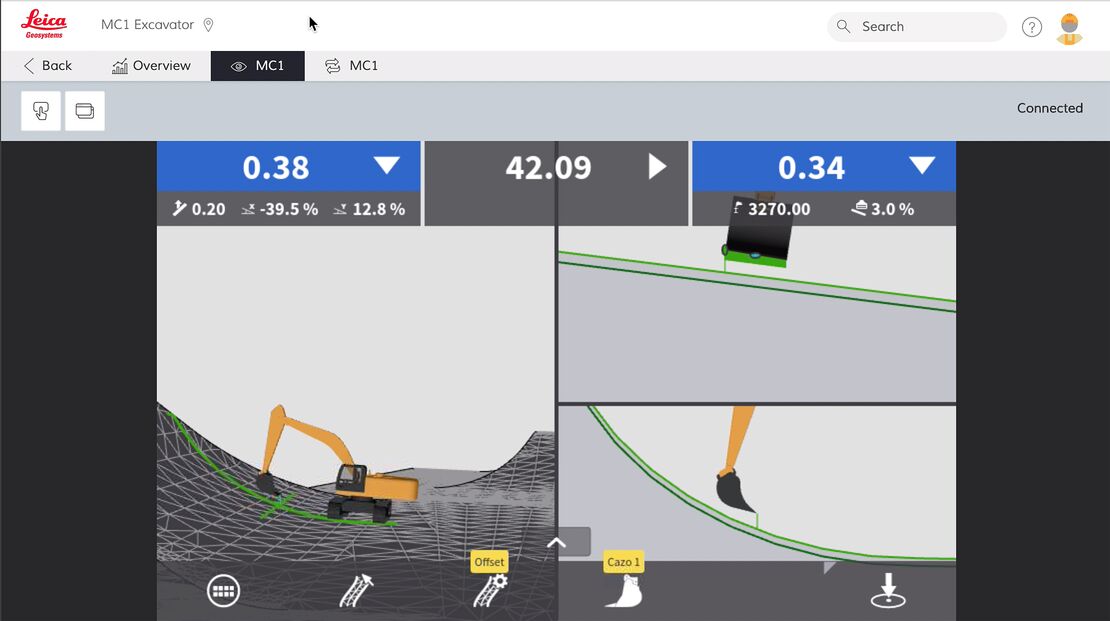

3D control systems use GPS machine control technology to project the site plan onto a monitor and generate real-time data for accurate positioning. With 3D, you know the placement of the cutting edge on a dozer or the bucket on an excavator, within half an inch.

3D is increasingly being used on smaller machines and by using it with a basic field controller you can keep costs down. The availability of modular solutions from Leica allows you to start with the solution you need and build it out as your business grows.

4. Hire out for 3D designs

Three-dimensional modeling combines the horizontal and vertical aspects of a construction project into an integrated digital model. Data is exported from the 3D models to the GPS machine control equipment that guides your dozers, pavers, excavators, rollers and other machines.

Contractors experienced in 3D machine control often have a 3D designer on staff, but you can hire firms to complete the designs. There are many companies specifically focused on providing this service, so don’t let this be a deterrent.

5. Rely on your Leica dealer for support

You may be hesitant to trust technology, but you’re not alone in the machine control journey. Our dealers are knowledgeable about Leica machine control products, and consider themselves your partner. We don’t just drop off the technology and say good luck. Everyone on your team will receive training. If issues arise, our dealers have the knowledge and support you need.

Leica ConX, our web-based interface to share positioning, reference models and constructed data in real time, allows dealers to tap into machines remotely, address issues and minimize downtime. Leica also has sales application engineers assigned to each dealer territory to provide additional support for customer issues.

Each of these tips can bring you closer to experiencing the benefits of machine control, while minimizing your risk. Contact our experts today to discuss your needs and next steps.

About the Author

Dennis Fay grew up around survey technology (his father and brother are licensed surveyors) and he continues to be amazed at what GPS technology can do. As Regional Sales Manager in the Southeast, Heavy Construction, Lecia Geosystems, part of Hexagon, he enjoys introducing contractors to machine control and working on a wide variety of construction projects.