In a service-oriented business, client satisfaction is the No. 1 goal. But as any entrepreneur who has ever entered a contest knows, it can’t hurt to have a secondary motivation to raise the bar on a firm’s overall capabilities.

When Doug Brinley first learned about the new MultiStation category in the annual Plan Contest at HxGN LIVE 2014, he knew he wanted to make an entry on behalf of Glapin Milphrey, LLC, the company he founded in 2012. “I wanted to submit a highly creative project that would explore the value of the MultiStation for our company and provide a competitive contest entry,” Brinley explains.

The Leica Nova Ms50 MultiStation, introduced in June 2013, is an innovative instrument that combines a high-precision total station with integrated high-definition 3D laser scanning capabilities to provide a versatile surveying solution that expands opportunities for its users. Glapin Milphrey has completed many successful projects for its clients, but Brinley believed that undertaking a unique project for the contest would be a greater benefit to the company than presenting past work. Most of the company’s current projects are inside buildings such as the Virginia Mason Medical Center in Seattle, and the Washington State Public Health Laboratory.

“These projects, while technically demanding, rarely extend above 100 feet,” Brinley says. “My goal was to do a long distance vertical application project that demonstrated the versatility of our approach and gave us the opportunity to improve speed-of-delivery, quality and labor reduction.”

Determining the Project’s Scope and Purpose

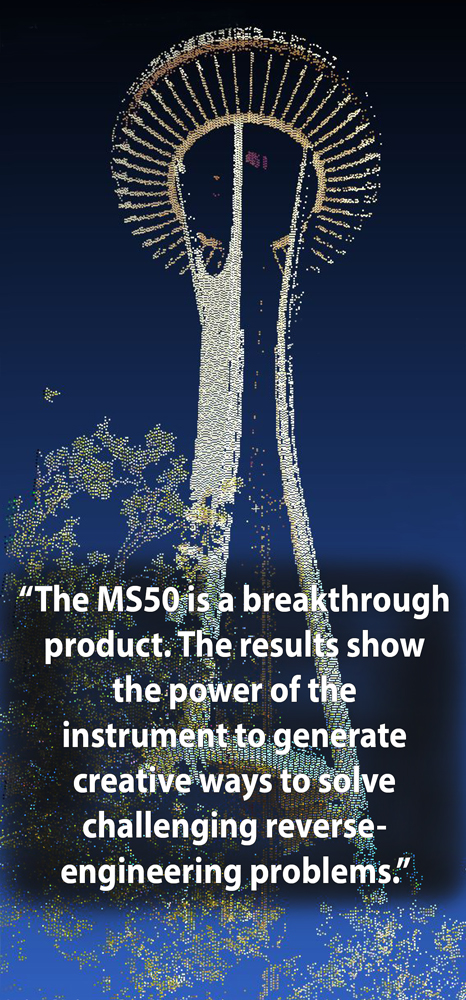

Brinley decided to scan the Seattle Space Needle for the project. At 605 feet high and 138 feet wide, the famous landmark represented a significant departure from the company’s work to that point and would have pushed the practical range limits of a conventional laser scanner. The integrated scanner in the MultiStation, however, has a range of up to 1,000 meters at slow scan speeds – plenty of range to provide high-quality scan data on a structure of the Space Needle’s height.

Brinley had another reason in mind when he chose to scan the Space Needle. Although he is comfortable and familiar with many of Leica Geosystems’ products (the company uses a ScanStation C10 as well as the P20 and TS15i), he had limited experience with the MultiStation. “I wanted to see how difficult it would be for a novice to achieve engineering-caliber results,” he says. If the project was successful, he planned to use it as a real-world training exercise.

Establishing Limits to Achieve Company Standards

The primary challenge of the project was to obtain all the field data information in one station setup. “In our company we want to get the maximum results from a limited amount of fieldwork,” Brinley explains. “We wanted to differentiate our entry in this regard. Most of the contest entries are highly crafted with hours or days of documentation, but we wanted a direct, focused approach to the project workflow.”

His goal was to complete the entire project in under four hours, which included travel to and from the site, scanning, processing, modeling, and then preparing and submitting it to the contest. To accomplish this, he would need to scan the Space Needle from a single station setup with less than 20 minutes of data collection.

The Space Needle stands in the middle of the busy Seattle Center. Part of the 1962 World’s Fair, today it is surrounded by businesses, tourists and commuters. Choosing a safe and effective location to setup and the right time of day to collect the scan data were important considerations in the project. Brinley chose a setup location on the public sidewalk north of the KIRO television station, which is directly across the street from the Space Needle. Six o’clock on a Saturday morning proved to be the best time to avoid the normal congestion of the site while taking advantage of natural lighting.

The lighting was particularly important for Brinley, because one of the key components of all Glapin Milphrey laser scanning deliverables is Leica TruViews, panoramic point cloud images that can be viewed, used for measurements and marked up over the Internet or through local PC files. “The imaging functions represent opportunities in building-related work,” Brinley explains. “We take care to set up the instrument to collect brilliant imaging with colors accurately represented for a professional appearance.”

Using the Integrated Scanner and the Robot to Complete the Fieldwork

The height of the Space Needle requires a steep sight angle for the scan. “In order to get good data results on such a tall structure, I constrained the field of view for the scan,” Brinley says. He used the scan definition routine built into the integrated scanner to identify the four corners corresponding to the area of the structure. The robotic functions of the MultiStation then automatically carried out his instructions without further input, leaving him free to observe conditions around the setup as the robot completed the operation.

The height of the Space Needle requires a steep sight angle for the scan. “In order to get good data results on such a tall structure, I constrained the field of view for the scan,” Brinley says. He used the scan definition routine built into the integrated scanner to identify the four corners corresponding to the area of the structure. The robotic functions of the MultiStation then automatically carried out his instructions without further input, leaving him free to observe conditions around the setup as the robot completed the operation.

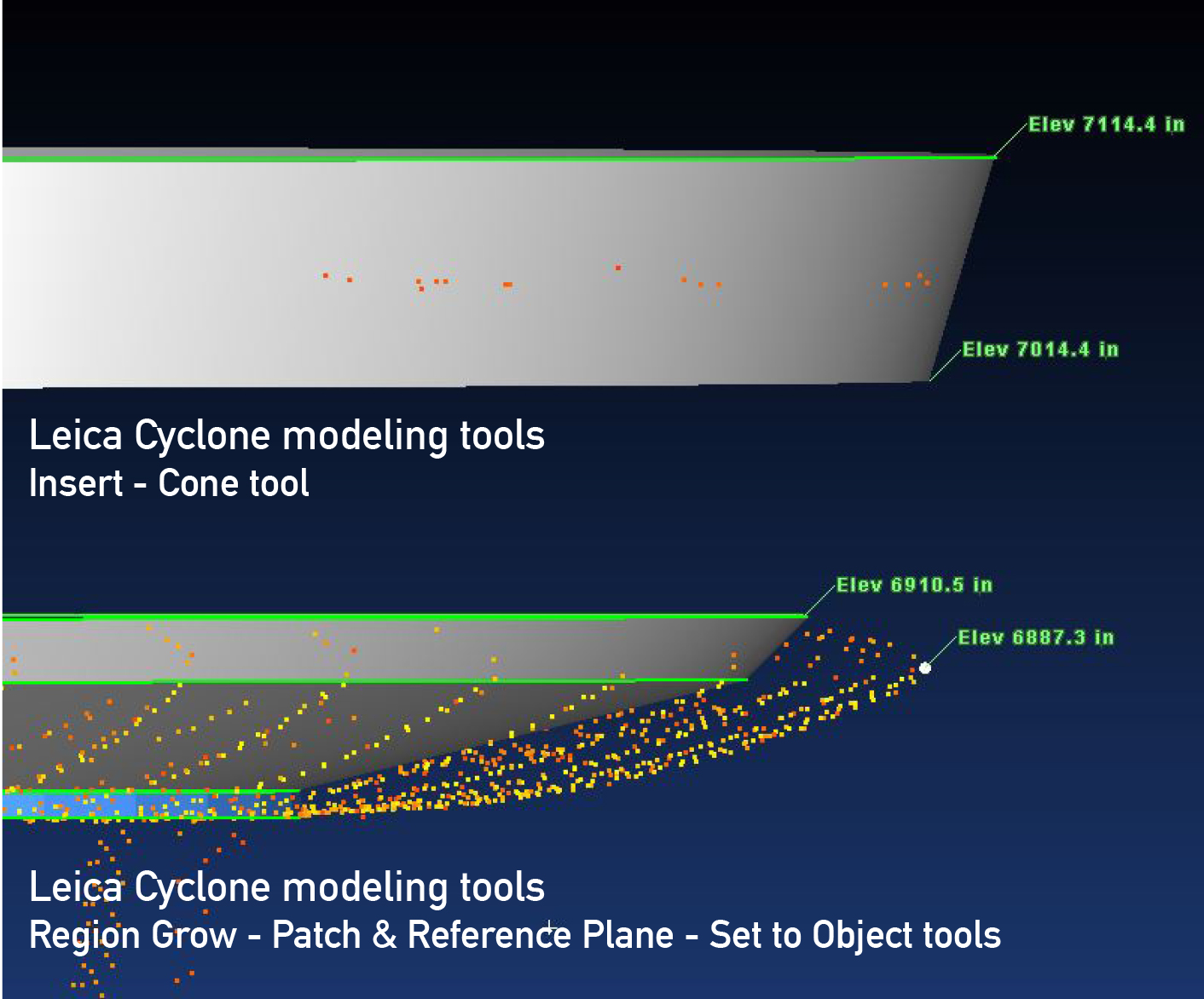

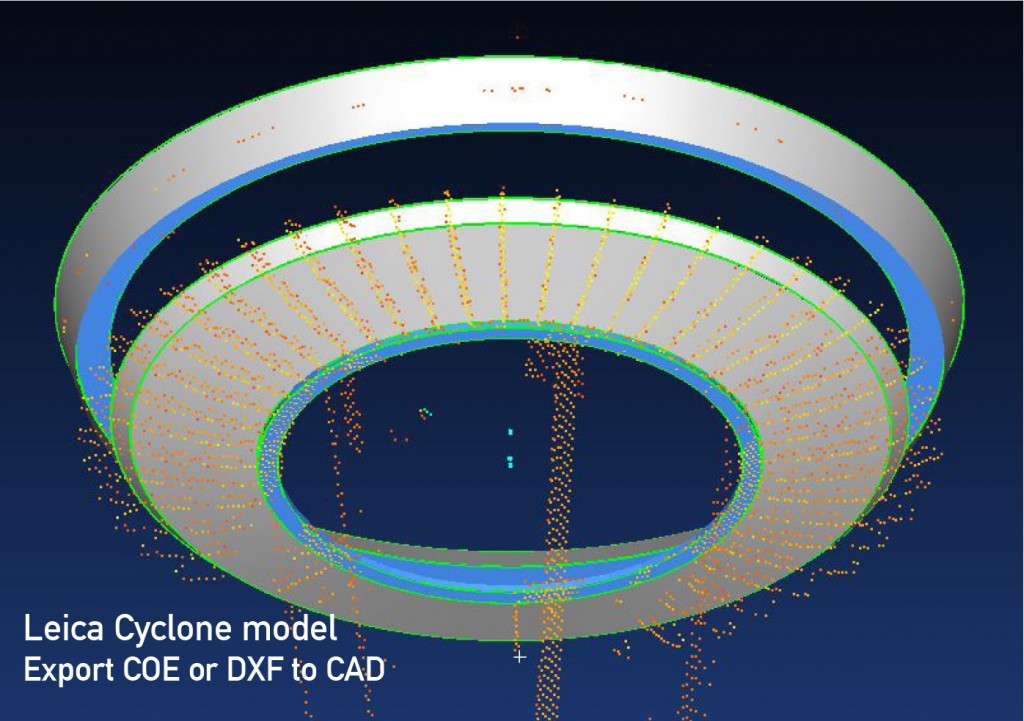

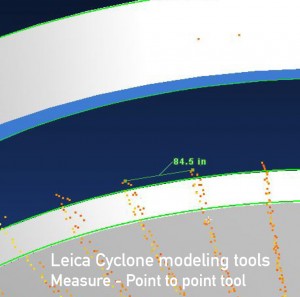

In addition to these fieldwork aspects, there was the complication of the structure itself. “The Space Needle is a complex monumental structure,” Brinley says. “I was particularly excited to use the Leica Cyclone cone tool for the concave assembly that conceals the revolving restaurant. That was a new challenge for me, and I enjoyed exploring the range of tools in the software.” The cone tool enables powerful surface modeling directly on the point cloud data, and this exercise expanded Brinley’s insight on possibilities for his company’s clients in the future.

“The MultiStation enabled me to gather a reasonable amount of useful data very quickly,” Brinley says. “The hardware and software are integrated, so I was able to seamlessly download and wrap up the project in the office in an hour-and-a-half using the Cyclone MODEL software module.”

Setting New Users on the Right Path

As Brinley hoped, the results of the Space Needle project allowed him to create a training exercise with a real world application. Rather than setting up the MultiStation and using it and a workflow in a static environment such as the company’s warehouse, new employees could be sent into the field to do this particular scan. Because the MultiStation’s datasets can be processed in Leica Infinity software, the workflow is simple and the multiple-scan registration step is not necessary.

Proficiency is a process with any tool, but this straightforward exercise gives Brinley a way to provide new users with effective, hands-on experience. “Trainees should be able to follow my written instructions to get a result similar to mine,” he says. “If they can’t replicate it, I’ll be able to pinpoint where they are getting off track. This will save my company time and expense in contrast to our previous training process.”

Applying the Results for Client Satisfaction

Brinley completed the entire project in about three hours, and he was pleased to see how easily he accurately and efficiently represented the distant structure of the Space Needle in a solids model. His work earned him an honorable mention in the 2014 Plan Contest. More importantly, however, completing the project without any roadblocks or issues gave Brinley more confidence in his own competency using the product and the software, as well as providing the company with a tool for educating new users on the equipment.

“The MultiStation is a breakthrough product,” Brinley says. “The contest results show the power of the instrument to generate creative ways to solve challenging reverse-engineering problems. Our clients will immediately be able to relate to these solutions.”