Operations managers and owners in the heavy construction sector know that achieving speed, productivity, safety, and accuracy in every single project is paramount. But working from faulty data can lead to inaccurate planning and budgeting as well as project delays and costly rework.

Over the past five years, the heavy civil construction industry has shifted its approach in how project data is gathered and analyzed. More and more companies are adopting a robust data gathering and analysis strategy that allows them to enhance efficiency and reduce risk from one project to the next.

Project Data Management and Analysis in the Cloud

To keep up with demanding timelines and schedules, companies have rethought data collection methods and processing strategies, turning to cloud-based services. These services, such as Leica ConX, allow project managers to share real-time project data with everyone who needs it. ConX, for example, enables visualization and validation of localized reference models, survey data, and constructed data while also carrying analysis tools for monitoring and reporting site productivity.

Doug Browning, senior survey manager at Archer United JV, said, “Utilizing cloud-based services for data transfer — whether it’s getting information to the field or getting the information as soon as it’s collected back to the office for processing — has saved us time and money.”

The Rising Tide of Technology Adoption

While larger construction sites such as highways have always relied heavily on survey data, there’s been a noticeable uptick in smaller and mid-size contractors incorporating technology into their workflows, according to Stephen Bridges, vice president of Construction Laser Inc.

“Before, these companies were depending on load counts, delivered materials, and calculated volumes to track progress,” said Stephen. “That operation is very slow to get back to the office for evaluation, if it even does. But with these cloud-based services, smaller companies are really adapting this technology and making it a part of their everyday workflows.”

The integration of cloud-based services, like ConX, allow for faster, more accurate data collection and processing. These tools enhance efficiency and enable contractors to better gauge progress, calculate volumes, and streamline the entire evaluation process.

Stephen said, “With machines being able to topo in automatics, anytime an operator is riding around in the machines, it’ll link through the cloud straight back to the ConX server and aggregate all that point data in real time. It’s in the office for evaluation instantly.”

Moreover, for typical site work projects, technologies like GPS equipment or drones have enabled contractors to collect existing topography data quickly and efficiently. This has allowed for instant identification of any discrepancies, resulting in significant time savings and enhanced project success rates.

“In the past, discrepancies were often seen only after the dirt was disturbed,” Stephen said. “But data transfer is so instant now that you can nip it in the bud on day one as soon as the trees have been removed from the site.”

The Future: Scanning and Reality Capture Technologies

Stephen sees widespread adoption of laser scanning as the next big step in the heavy construction industry.

“Reality capture is the future of construction, such as ground penetrating radar getting underground utilities,” Stephen said. “A laser scanner that gets millimeter accurate data is way faster and safer than other measurement methods.”

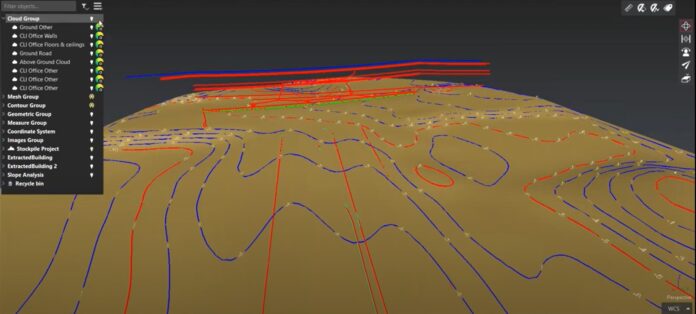

With a laser scanner such as the Leica RTC360, surveying construction sites takes a fraction of the time than using prisms and total stations. Moreover, the collected data is generated into a point cloud that can be used for contour visualization, volume measurements, 3D object modeling, clash detection, and accurate material ordering. Faster measurement collection combined with millimeter-level accuracy means time saved and errors avoided.

With the growing adoption of cloud-based data transfer and laser scanning across the heavy construction industry, an increasing number of companies are creating an end-to-end data capture and analysis workflow that helps to ensure project efficiency, safety, accuracy, and client satisfaction.

To speak with a heavy construction expert who can guide you on your data management and technology journey, contact us.