Radio frequency (RF) pipe and cable locators and electromagnetic locators are the most common tools used to detect underground utilities on construction jobsites. But these methods only detect conductive (metallic) objects. Increasingly, construction crews also need to be able to locate, detect and trace underground pipes and cables that are nonmetallic. For this application, ground penetrating radar (GPR) is the ideal technology. But what if you don’t have someone with the skill and training to interpret the results?

Traditional GPR produces a radar gram or hyperbola of underground density changes. Anyone who is not familiar with these images won’t know whether they’re looking at a cable, a pipe, or something else. It’s not clear what the bumps on the screen represent. Learning how to read a radar gram is not a quick and simple process. Data can be misinterpreted, and utilities can be missed.

Exploiting the full benefits of GPR requires an approach that makes underground detection more accurate and more accessible.

This approach already exists, and it’s creating a renewed demand for GPR technology.

GPR Innovations Reveal New Information

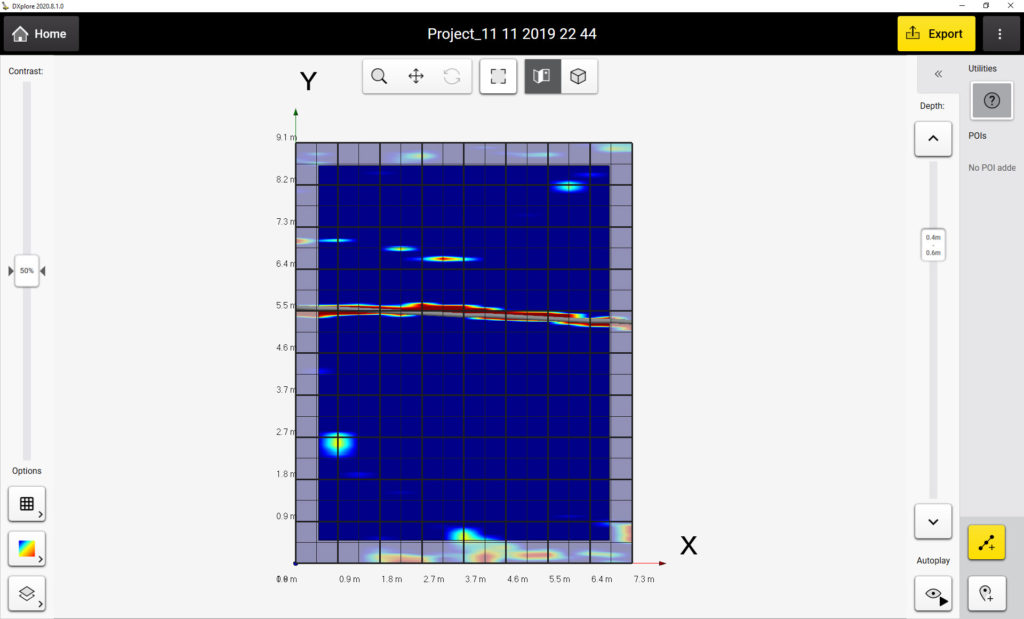

The most recent GPR innovations feature large, daylight-readable screens that make it easy to setup the system, integrate GNSS, define the collection grid and access project information.

These systems display results in real time using tomographic imaging, which is significantly easier to interpret than a hyperbola. We can look for a visual indicator that we have a utility. From there, we can rely on intelligent algorithms in the software to identify the utility and the exact location—the x,y position, as well as the depth.

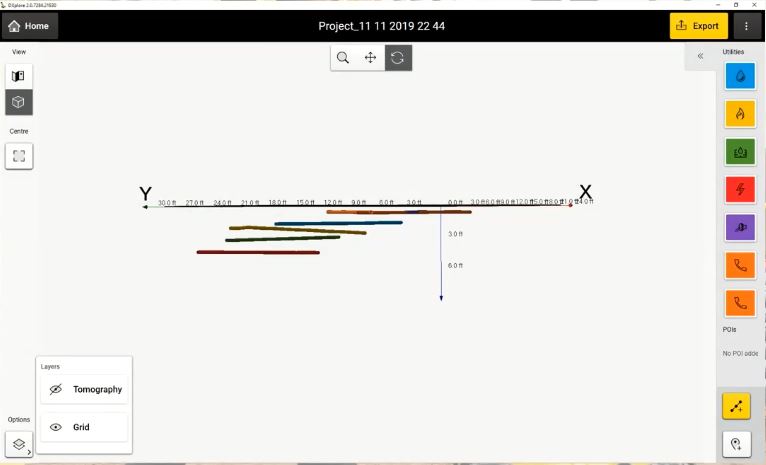

3D Visualizations Provide Invaluable Insights

We can also see the utilities in 3D and how they interact with each other, so we can easily identify any conflicts and determine the best place to dig to avoid a utility strike.

And we no longer have to wait until the data is sent to the office and post-processed. That information is all available in the field immediately. The data can go in any coordinate system. We can also include other points of interest, such as fire hydrants, lamp posts, and manholes, which adds even more context.

With the latest GPR technologies, construction crews can easily capture a complete and accurate picture of what’s happening underground. This capability mitigates the risk of utility strikes and accelerates construction progress for a safer, more efficient jobsite.

To speak with a construction expert who can guide you on your technology journey, contact us.